close

Choose Your Site

Global

Social Media

| Horse Power: | |

|---|---|

| Power supply: | |

| Energy regulation: | |

| Availability: | |

| Quantity: | |

SLDS

RFC

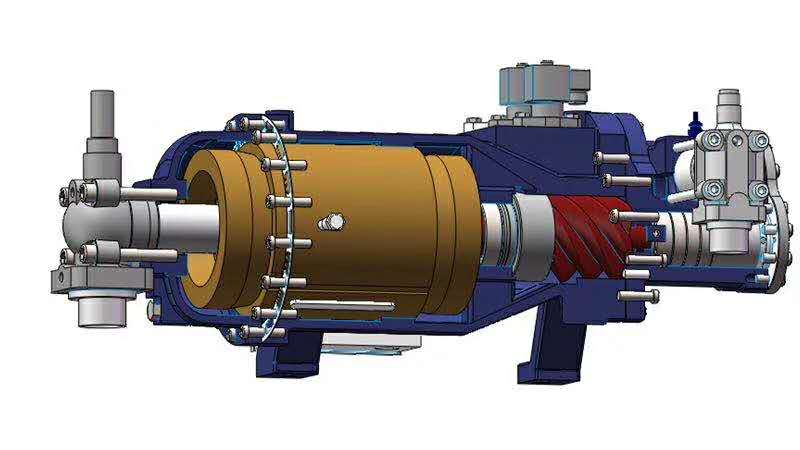

Single-stage compressors struggle with ultra-low temperatures (-60°C to -30°C) due to high pressure ratios and motor strain. The Semi-Hermetic Screw Double-Stage Compressor (SLDS series) solves this by splitting compression into two stages—low-pressure (LP) and high-pressure (HP)—reducing energy use by 20% and extending motor life by 50% vs. single-stage ULT compressors.

Vaccines, blood products, and gene therapies require stable -40°C to -60°C storage. The SLDS series maintains ±1°C temperature precision, preventing sample degradation (a risk with single-stage compressors, which fluctuate by ±3°C). Its hermetic design also eliminates contamination risks (critical for FDA-compliant facilities).

Freshly caught fish must be frozen from 25°C to -40°C within 2 hours to preserve texture and freshness. The SLDS series’ dual-stage compression achieves cooling rates of 0.5°C/min—30% faster than single-stage units—reducing spoilage rates from 8% to 2% for long-haul shipping.

Aerospace and electronics industries need chambers for cold shock testing (-60°C to 100°C). The SLDS series’ rapid temperature adjustment (from -60°C to 20°C in 30 minutes) and stable performance make it ideal for testing components like circuit boards or aircraft parts.

• Low-Pressure (LP) Stage: Handles initial cooling from ambient temperature to -30°C using large-diameter screws (67-92mm) for high refrigerant flow.

• High-Pressure (HP) Stage: Further cools to -60°C using smaller-diameter screws (42-67mm) for high pressure.

• Intercooler: Removes heat between stages, reducing motor strain and improving efficiency.

• LP Casing: Cryogenic-grade stainless steel (316L) resists brittleness at -60°C—unlike standard steel, which cracks at -40°C.

• HP Screws: Titanium nitride-coated alloy steel, resistant to wear from high-pressure refrigerant flow.

• Motor Windings: Class C insulation (tolerates 220°C), preventing burnout from ULT heat generation.

The SLDS series includes:

• Phase-Loss/Reverse Protection: Shuts down if power phases are reversed or lost (prevents motor damage).

• Winding Temperature Sensors: Triggers shutdown if temperatures exceed 110°C.

• Pressure Relief Valves: Releases excess pressure in the HP stage, avoiding casing damage.

• Refrigerant Compatibility: R22 (for -30°C to -40°C), R404A/R507 (for -40°C to -60°C).

• Motor Type: 3-phase, 2-pole semi-hermetic asynchronous motor (high torque for ULT start-up).

• Capacity Adjustment: 100%, 50%, 25% step regulation (adapts to low-load periods).

• Strength Test Pressure: 42 bar (ensures casing safety at high pressure).

We collaborate with your engineering team to design custom cold storage or testing chambers, including:

• Refrigerant piping (sized for dual-stage flow).

• Temperature control systems (compatible with PLCs).

• Insulation (e.g., polyurethane foam for -60°C use).

We also provide 3D models of the integrated system for approval.

Our 8-hour training sessions cover ULT-specific maintenance:

• Oil replacement in sub-zero conditions (using low-viscosity oil).

• Leak testing with helium (more sensitive for ULT systems).

• Safe handling of cryogenic refrigerants (R404A/R507).

Training is available on-site or via live video for global teams.

• Warranty: 24 months standard; 36 months for biopharmaceutical clients (compliant with FDA requirements).

• Spare Parts: Dedicated ULT parts (e.g., cryogenic seals, LP/HP screws) are stocked in global warehouses—delivered within 2 business days for urgent cases.

Optional IoT-enabled sensors track:

• Evaporation/condensing temperatures.

• LP/HP pressure ratios.

• Motor current and temperature.

Alerts are sent via mobile app if anomalies are detected, allowing proactive maintenance and preventing costly failures.

| Model | SLD-S | 230S-50 | 420S-100 | 640S-150 | |||

| Evaporation temperature | ℃ | -60~-30(R22); -60~-30(R404A/R507 | |||||

| Rotate speed | r/min | 2960/3552 | |||||

| Low pressure displacement | m3/h | 235/282 | 420/504 | 641/769 | |||

| High pressure displacement | m3/h | 102 / 122 | 192/230 | 235/282 | |||

| Low pressure casing size | mm | 67 | 80 | 92 | |||

| High pressure casing size | mm | 42 | 54 | 67 | |||

| Capacity adjustment range | % | Three Stage(100,50,25) | |||||

| Power supply | V/Hz | 3Ph / 380 V / 50 Hz | |||||

| Motor form | 3 Phase,2 pole,Semi-Hermitic asynchronous motor | ||||||

| Startup mode | “Y- ”or“△” | ||||||

| Protection devices | Less of Phase ,reverse phase protection, winding temperature protection | ||||||

| Strength test | g | 42 | |||||

| Rated power | Hp/kW | 60/45 | 125/94 | 175/131 | |||

| Starting current/Y | A | 137 | 276 | 374 | |||

| Starting current/△ | A | 448 | 878 | 1155 | |||

| Rated current | A | 85 | 170 | 237 | |||

| Maximum working current | A | 108 | 207 | 290 | |||

| Wight | kg | 410 | 620 | 870 | |||

Key/:

Qo:coolingcapacity/冷量( kW)

Pa :inputpower/输入电功率(kW)

Te :Evaporatingtemperature/蒸发温度(℃)

Tc:Condensingtemperature/冷凝温度(℃)

50Hzfrequency /频率

Liquid subcooling/液体过冷度 5K

Suction gas superheat/吸气过热度 10K

Require additionalcooling

| 型号Model | A | B | C | D | E | F | G | H | K | L | M | N | P |

| SLD230S-50 | 1271 | 526 | 216 | 243 | 150 | 224 | 221 | 468 | 448 | 574 | 457 | 863 | 193 |

| SLD420S-100 | 1520 | 637 | 250 | 290 | 198 | 290 | 239 | 530 | 567 | 745 | 618 | 1094 | 209 |

content is empty!