close

Choose Your Site

Global

Social Media

| Power supply: | |

|---|---|

| Lubricant: | |

| Horse power: | |

| Availability: | |

| Quantity: | |

BFS

DMZL

The BFS Series is a compact, cost-effective semi-hermetic compressor designed for 5–15HP commercial and light industrial applications. It balances power and space efficiency, making it ideal for businesses that need reliable cooling without the footprint or cost of industrial-grade systems.

• Convenience Stores & Small Retailers: Powers under-counter beverage coolers, small frozen food displays, and dairy cases. Uses R134A to keep products at 5℃, with a compact design that maximizes floor space for merchandise.

• Light Industrial & Laboratory Use: Maintains 2–8℃ for sample storage in university research labs, local medical clinics, or small manufacturing facilities. Precise temperature control (±0.5℃) ensures compliance with laboratory or medical standards.

• Customer-Facing Businesses: Quiet operation (<70 dB) makes it suitable for floral shops, bakeries, and cafes—enhancing customer experience while keeping flowers fresh (10–12℃) or bakery ingredients cool (20℃).

• 2–3 Cylinder Configuration: Optimized cylinder diameter (47.6–64mm) and stroke (37–64mm) deliver efficient cooling for small systems. The balanced design reduces vibration and noise, critical for customer-facing or office-adjacent spaces.

• Splash Lubrication System: Simple, low-maintenance lubrication ideal for light-duty applications (8–12 hours of daily use). Eliminates the need for complex lubrication pumps, reducing maintenance costs for small businesses.

• Cast Iron Housing: Lightweight yet robust cast iron construction (62–172 kg) for easy installation. A corrosion-resistant finish protects against moisture in damp environments (e.g., floral shops, bakery backrooms).

• High-Quality Internal Parts: Valve plates made from durable steel and precision-machined pistons ensure reliable performance. These components are tested to withstand 8,000+ hours of use, meeting the needs of small businesses with moderate cooling demands.

• Replacement for Outdated Models: Designed to replace legacy Copeland and Bitzer compressors (e.g., Copeland C-0500, C-1000, Bitzer 2GC). Identical mounting points and refrigerant compatibility simplify retrofits, avoiding the need for system redesign.

• Drop-In Installation: No modifications to existing piping or electrical systems are required for most retrofits. This reduces installation time and costs for businesses upgrading from older, inefficient compressors.

• Free Cross-Reference Guide: A detailed tool to match BFS models with outdated Copeland/Bitzer compressors (e.g., BFS151 = Copeland C-1500). Includes dimensions, refrigerant compatibility, and electrical specifications to simplify retrofit decisions.

• Retrofitting Support: Our technical team provides free advice for retrofits, including compatibility checks, installation tips, and performance calibration to ensure the compressor integrates seamlessly with existing systems.

• Bulk & Small-Quantity Orders: Minimum order quantity of 1 unit for small businesses, with bulk pricing discounts for distributors or HVAC contractors ordering 10+ units. Production capacity of 5000 units/month ensures timely delivery for large orders.

• Global Logistics: Shipping from Ningbo port with FOB negotiable pricing. Supports L/C and T/T payment terms, making it easy for international clients (e.g., European convenience store chains) to place orders.

• Online Technician Training: Free courses covering installation, maintenance, and troubleshooting are available via our website. Modules include videos, diagrams, and quizzes to ensure technicians master key skills.

• Warranty & Parts: 1-year standard warranty, with optional 2-year extended coverage. A global network of parts warehouses ensures fast delivery of genuine components, reducing downtime for small businesses.

• Local Service Partners: Collaborations with local HVAC service providers in key regions ensure on-site support for installation or repairs, even for small orders.

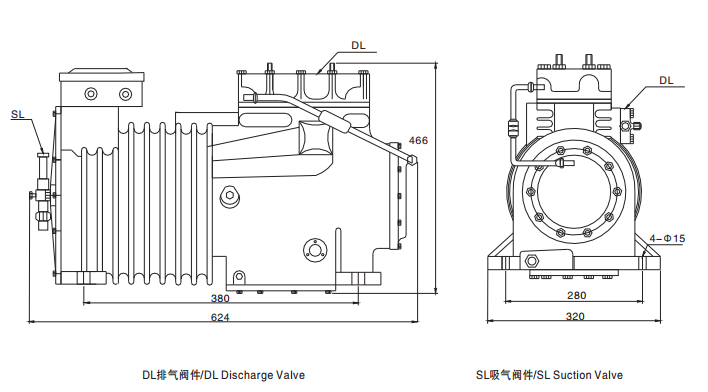

| C type Model | Nominal Power HP/KW | Displacement m³/h@ 50Hz | Number of Cylinders×Diameter×Stoke | Exhaust & Suction Valve mm/IN | Oil Volume L | Power V/φ/Hz | Electrical Parameter | Crankcase Heater (220V)W | Oil Supply Method | Weight (with lubricant) Kg | ||

| DL Exhaust Valve | SL Suction Valve | Max Operating Current (A) | Starting/ Locked Current (A) | |||||||||

| BFS31 | 3/2.2 | 12.2 | 2×φ47.6×39.2 | φ16 | Φ19.05 | 1.25 | 220-240△/380-420Y/3/50 265-290△/440-480Y/3/60 | 5.2 | 24/26 30/32 | 60 | Splashing Lubrication | 62 |

| BFS41 | 4/3 | 14.7 | 2×φ54×37 | Φ19.05 | Φ25.4 | 1.25 | 7.6 | 38/44 | 60 | 85 | ||

| BFS51 | 5/3.7 | 18.4 | 2×φ54×46 | Φ19.05 | Φ25.4 | 1.85 | 7.6 | 38/44 53/58 | 60 | 87 | ||

| BFS81 | 8/5.5 | 26.6 | 2×φ64×48 | Φ25.4 | Φ31.75 | 3.5 | 15 | 74/81 | 120 | 133 | ||

| BFS101 | 10/7.5 | 36 | 2×φ64×64 | Φ25.4 | Φ31.75 | 3.5 | 15.6 | 93/103 112/126 | 120 | 137 | ||

| BFS151 | 15/10.5 | 54 | 3×φ64×64 | Φ28 | Φ38.1 | 4.8 | 22.3 | 133/150 162/184 | 180 | 172 | ||

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | ||||||||

| Evaporating Temperature ℃ | ||||||||||

| 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | |||

| BFS31 BFS31A | 30 | Qo | 8430 | 6800 | 5350 | 4070 | 2730 | 1860 | ||

| Pe | 2.33 | 2.38 | 2.15 | 1.95 | 1.7 | 1.45 | ||||

| 40 | Qo | 7380 | 5820 | 4530 | 3370 | |||||

| Pe | 2.7 | 2.55 | 2.35 | 2.05 | ||||||

| 50 | Qo | 6300 | 5820 | 3840 | 2560 | |||||

| Pe | 3 | 2.78 | 2.48 | 2.15 | ||||||

| BFS41 | 30 | Qo | 14350 | 12330 | 10590 | 8430 | 6750 | 5180 | 3840 | 2500 |

| Pe | 3.01 | 2.93 | 2.8 | 2.68 | 2.5 | 2.3 | 2.02 | 1.638 | ||

| 40 | Qo | 13250 | 10820 | 9200 | 7270 | 5700 | 4250 | |||

| Pe | 3.6 | 3.45 | 3.23 | 3 | 2.73 | 2.43 | ||||

| 50 | Qo | 11570 | 9780 | 7910 | 6160 | 4760 | 3430 | |||

| Pe | 4.18 | 3.93 | 3.6 | 3.25 | 2.88 | 2.45 | ||||

| BFS51 | 30 | Qo | 13140 | 10760 | 8720 | 6860 | 5300 | 3840 | ||

| Pe | 3.5 | 3.35 | 3.15 | 2.9 | 2.63 | 2.3 | ||||

| 40 | Qo | 11750 | 9600 | 7620 | 6050 | |||||

| Pe | 4.08 | 3.8 | 3.5 | 3.15 | ||||||

| 50 | Qo | 10380 | 8370 | 6570 | 5030 | |||||

| Pe | 4.55 | 4.2 | 3.78 | 3.3 | ||||||

| BFS81 | 30 | Qo | 28140 | 22790 | 19300 | 15580 | 12320 | 9650 | 7270 | 5350 |

| Pe | 5.07 | 4.91 | 4.69 | 4.42 | 4.1 | 3.75 | 3.35 | 2.95 | ||

| 40 | Qo | 25580 | 20930 | 16970 | 13480 | 10500 | 8250 | |||

| Pe | 6.25 | 5.85 | 5.42 | 4.97 | 4.5 | 4 | ||||

| 50 | Qo | 23260 | 19180 | 14650 | 11740 | 9070 | 6740 | |||

| Pe | 7.03 | 6.55 | 6 | 5.4 | 4.75 | 4.15 | ||||

| BFS101 | 30 | Qo | 26510 | 21620 | 17450 | 13720 | 10700 | 8140 | ||

| Pe | 7.15 | 6.75 | 6.25 | 5.75 | 5.2 | 4.65 | ||||

| 40 | Qo | 23730 | 19420 | 15350 | 12100 | |||||

| Pe | 8.2 | 7.6 | 6.9 | 6.25 | ||||||

| 50 | Qo | 21040 | 17090 | 13490 | 10580 | |||||

| Pe | 9.15 | 8.3 | 7.5 | 6.65 | ||||||

| BFS151 | 30 | Qo | 38960 | 31750 | 25350 | 20170 | 15700 | 11980 | ||

| Pe | 10.3 | 9.8 | 9.1 | 8.25 | 7.4 | 6.6 | ||||

| 40 | Qo | 34890 | 28260 | 22560 | 17800 | |||||

| Pe | 11.8 | 10.9 | 9.9 | 8.85 | ||||||

| 50 | Qo | 30700 | 24880 | 19650 | 15580 | |||||

| Pe | 13.1 | 11.9 | 10.75 | 9.5 | ||||||

| BFS151H | 30 | Qo | 50320 | 42560 | 34190 | 27030 | 22560 | |||

| Pe | 13.6 | 12.93 | 12.1 | 10.95 | 10 | |||||

| 40 | Qo | 48430 | 40480 | 32460 | 25620 | |||||

| Pe | 14.9 | 14.1 | 13.1 | 11.7 | ||||||

| 50 | Qo | 46740 | 38600 | 30930 | 30930 | |||||

| Pe | 15.9 | 15 | 13.75 | 12.35 | ||||||

| Based on 20℃ suction gas temperature,50Hz,without liquid subcooling. | ||||||||||

| VARICOOL system,additional cooling,position of suction valve changed. | ||||||||||

| Additional cooling or limited suction gas temperature. | ||||||||||

| Additional cooling and CIC system. | ||||||||||

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | |||||||||||

| Evaporating Temperature ℃ | |||||||||||||

| 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | |||

| BFS51 | 30 | Qo | 24000 | 22200 | 18600 | 15400 | 12600 | 10200 | 8500 | 6700 | 5300 | 4000 | 3000 |

| 40 | Qo | 20400 | 18900 | 15800 | 13100 | 10700 | 8700 | 7200 | 5700 | 4500 | 3400 | 2600 | |

| BFS81 | 30 | Qo | 31400 | 28700 | 24000 | 20000 | 16400 | 13400 | 10700 | 8500 | 6500 | 4900 | 3700 |

| 40 | Qo | 26400 | 24100 | 20200 | 16800 | 13800 | 11300 | 9000 | 7100 | 5500 | 4200 | 3100 | |

| BFS101 | 30 | Qo | 44800 | 44200 | 35100 | 29000 | 23900 | 19400 | 15600 | 12300 | 9500 | 7200 | 5300 |

| 40 | Qo | 38100 | 35600 | 29800 | 24600 | 20300 | 16500 | 13200 | 10500 | 8100 | 6100 | 4500 | |

| BFS151 | 30 | Qo | 69000 | 64500 | 54300 | 45200 | 37300 | 30500 | 25600 | 19600 | 15300 | 11700 | 8900 |

| 40 | Qo | 58700 | 54800 | 46200 | 38400 | 31700 | 25900 | 21800 | 16700 | 13000 | 9900 | 7500 | |

| Based on 20℃ suction gas temperature,50Hz,without liquid subcooling. | |||||||||||||

| Additional cooling or limited suction gas temperature. | |||||||||||||

| Additional cooling and CIC system. | |||||||||||||

The BFS series is a compact, cost-effective semi-hermetic reciprocating compressor launched by Zhejiang Daming Refrigeration (DMZL). It is mainly designed for commercial and light industrial scenarios, with a power range of 5HP-15HP. It balances cooling power and space efficiency, avoiding the large size and high cost of industrial-grade equipment.

It is compatible with 4 mainstream refrigerants to meet different cooling needs:

• R134A (commonly used in commercial refrigeration, such as convenience store beverage coolers)

• R22, R404A, R507A (suitable for low-temperature storage or industrial cooling scenarios)

It is mainly adapted to three types of scenarios, with optimized performance for different needs:

• Convenience stores/small retailers: Powers under-counter beverage coolers and small frozen food display cabinets. It uses R134A to maintain a constant temperature of 5°C, and its compact design maximizes the display space for goods.

• Light industry/laboratories: Provides a 2–8°C environment for sample storage in university laboratories and community medical clinics. The temperature control accuracy reaches ±0.5°C, meeting medical and experimental standards.

• Customer-facing locations (floral shops, bakeries, cafes): Operates at a noise level of <70dB, maintaining the freshness of flowers at 10–12°C and keeping bakery ingredients cool at 20°C without affecting the customer experience.

It supports multiple power supply specifications, compatible with the electricity standards of major regions worldwide:

• 380-420V/3-phase/50Hz

• 440-480V/3-phase/60Hz

• 220-240V/3-phase/50Hz

It can be directly replaced with low installation costs:

• It is designed to replace old Copeland models (e.g., C-0500, C-1000) and old Bitzer models (e.g., 2GC), with identical mounting points and refrigerant compatibility.

• Most scenarios support "drop-in installation"—no modifications to existing piping or electrical systems are required, significantly reducing upgrade time.