close

Choose Your Site

Global

Social Media

| Horse Power: | |

|---|---|

| Color: | |

| Power supply: | |

| Lubricant: | |

| Optional accessories: | |

| Availability: | |

| Quantity: | |

6WDS

DMZL

As a core product of Daming Refrigeration, the China DMZL 6-Cylinder Ultra-Freezing Double-Stage Semi-Hermetic Piston Compressor is engineered for ultra-low temperature refrigeration scenarios (-45℃ to -70℃). It integrates robust performance, energy efficiency, and durability, making it ideal for industries requiring stable deep-freezing, such as pharmaceutical storage, seafood processing, and industrial raw material preservation. Its double-stage compression technology and hermetic structure address the pain points of high energy consumption and refrigerant leakage in traditional ultra-freezing equipment, providing a reliable solution for global customers.

Compliant with CDC and FDA cold chain standards, this compressor maintains a consistent temperature range of -60℃ to -70℃—a critical requirement for storing temperature-sensitive medical products like COVID-19 vaccines, influenza biologics, and protein-based pharmaceuticals. Its double-stage compression design reduces discharge temperature to ≤85℃ (at -35℃ evaporation), effectively preventing thermal damage to active ingredients in drugs. Additionally, the hermetic structure ensures a leak rate of <0.1 g/year, avoiding refrigerant contamination that could compromise the safety of medical supplies.

For seafood processing facilities, especially those focused on high-value products like fresh shrimp, scallops, and premium fish, this compressor enables rapid flash-freezing. It cools seafood from 10℃ to -25℃ in just 45 minutes, which preserves cell structure, locks in natural flavor, and extends shelf life by 50% compared to conventional freezing methods. This performance meets the strict quality requirements of international export markets (e.g., EU, US), helping processors expand their global reach without compromising product quality.

In industrial settings, the compressor supports 200-600 m³ deep-freeze warehouses used to store rubber compounds, metal powders, and chemical raw materials—all of which require ultra-low temperatures to maintain chemical stability. The double-stage compression ensures uniform cooling across large storage spaces (temperature variation ≤2℃), eliminating hot spots that could cause material degradation. Its high displacement (up to 151.6 m³/h@50Hz) also enables quick temperature recovery after warehouse doors are opened, reducing energy waste in high-frequency operation scenarios.

• Integrated Hermetic Structure: The motor and compressor body are integrally cast, sharing a sealed internal space. This eliminates the need for a shaft seal, a common source of refrigerant leakage in open compressors, and reduces maintenance needs by 30%.

• Optimized Double-Stage Compression: Compression is split into two stages, with intermediate pressure controlled at 0.32 MPa and final pressure at 1.3 MPa. This design reduces valve wear by 40% and cuts energy consumption by 18% compared to single-stage compressors of the same power.

• Space-Saving Compact Layout: Advanced component assembly technology minimizes the compressor’s volume, saving 12% of installation space compared to similar 6-cylinder ultra-freezing compressors. This is particularly beneficial for facilities with limited equipment rooms.

• Chrome-Plated Piston Rings & Aluminum Pistons: The chrome plating enhances wear resistance, while the lightweight aluminum piston reduces friction. Together, these components extend the compressor’s service life to 8,000+ operating hours—20% longer than standard piston materials.

• Hardened Steel Crankshaft & Low-Friction Bearings: The crankshaft is heat-treated to withstand high torque, and the bearings use a special lubrication coating that reduces vibration to ≤65 dBA. This ensures quiet, stable operation even in 24/7 duty cycles.

• Imported Spring Steel Valve Reeds: Made from high-strength spring steel sourced from Germany, the valve reeds can withstand 1.5 million cycles of opening and closing without deformation. This improves compression efficiency by 8% and reduces the risk of unexpected downtime.

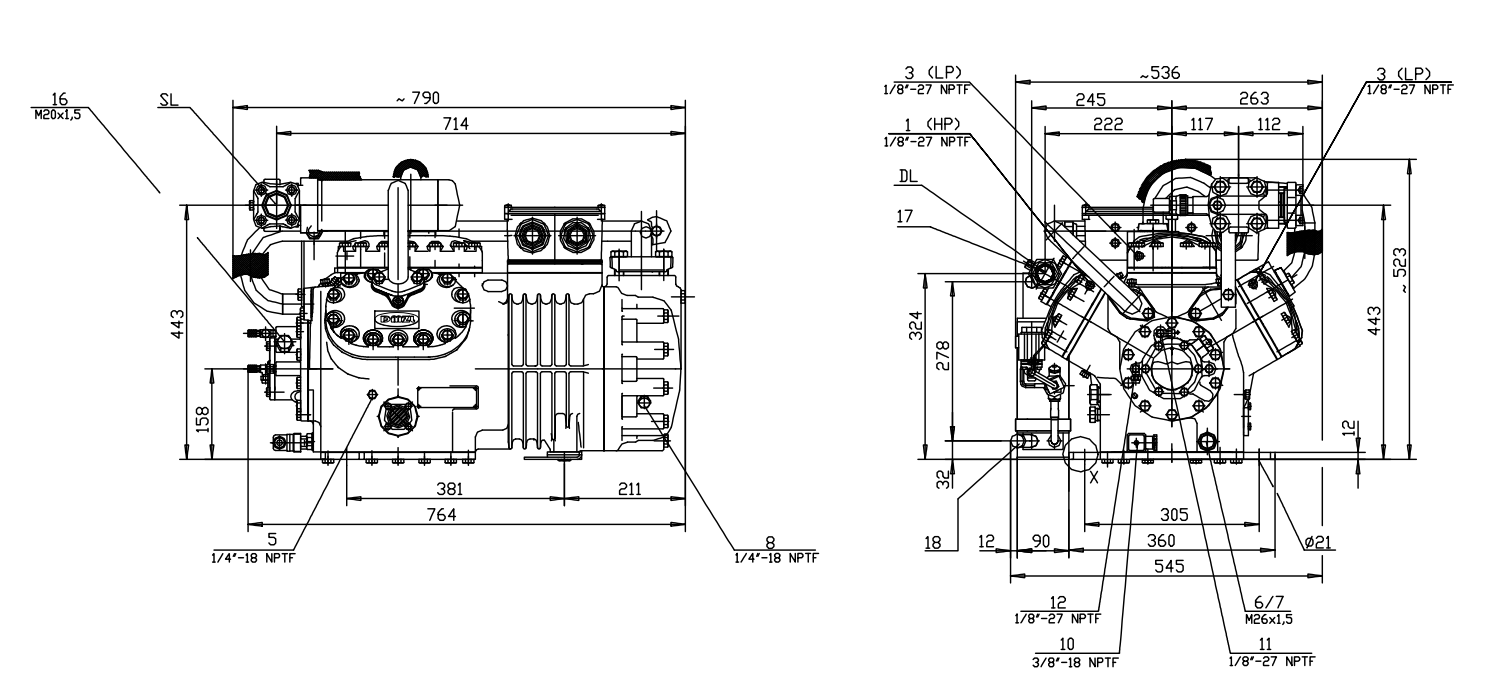

• Detailed Guidance Materials: We provide 3D installation drawings (in CAD and PDF formats) and a step-by-step installation manual, covering pipeline connection, electrical wiring, and pressure testing.

• On-Site & Remote Support: Certified engineers are available for on-site guidance for large-scale projects (e.g., 500+m³ cold storage). For urgent issues, our 24/7 online technical team offers real-time troubleshooting via video call, resolving 80% of problems within 1 hour.

• Global Spare Parts Network: With warehouses in the USA, Germany, and Singapore, we ensure spare parts (e.g., valve plates, piston rings, oil filters) are delivered within 3-5 business days to most regions.

• Customized Maintenance Plans: Based on the compressor’s operating hours and application scenario, we design quarterly or annual maintenance plans. These include oil level checks, valve performance testing, and crankcase heater functionality inspections to prevent potential failures.

• Comprehensive Coverage: A 2-year comprehensive warranty covers the entire unit, including the motor, compressor body, and valves.

• Extended Protection for Key Components: Critical parts like the crankshaft and piston rings receive a 5-year extended warranty, providing long-term peace of mind for customers.

| DMZL Model | Nominal Power HP/KW | Displacement m³/h@ 50Hz | Number of Cylinders×Diameter×Stoke | Exhaust & Suction Valve mm/IN | Oil Volume L |

Power V/φ/Hz |

Electrical Parameter | Crankcase Heater (220V)W | Oil Supply Method | Weight (with lubricant) Kg |

||

| DL Exhaust Valve | SL Suction Valve | Max Operating Current (A) | Starting/ Locked Current (A) | |||||||||

| 4VDS-12.2 | 12/8.8 | 42.3/27 | 4×φ75/60×55 | φ28 | φ35 | 4.5 | 380-420YY/3/50 440-480YY/3/60 | 24 | 69/113 | 140 | Forced-lubrication | 180 |

| 6WDS-16.2 | 16/11.7 | 63.5/31.8 | 6×φ65/65×55 | φ35 | φ42 | 4.75 | 380-420YY/3/50 440-480YY/3/60 | 31 | 81/132 | 140 | Forced-lubrication | 209 |

| 6WDS-20.2 | 20/15 | 110.5 | 6×φ70/70×55 | φ35 | φ42 | 4.75 | 380-420YY/3/50 440-480YY/3/60 | 37 | 97/158 | 140 | Forced-lubrication | 220 |

| 6WDS-25.2 | 25/18.5 | 126.8 | 6×φ75/75×55 | φ35 | φ42 | 4.75 | 380-420YY/3/50 440-480YY/3/60 | 45 | 116/193 | 140 | Forced-lubrication | 233 |

| 6WDS-30.2 | 30/22 | 151.6 | 6×φ82/82×55 | φ35 | φ42 | 4.75 | 380-420YY/3/50 440-480YY/3/60 | 53 | 135/220 | 140 | Forced-lubrication | 234 |

R404A/R507A

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | ||||||||||

| Evaporating Temperature ℃ | ||||||||||||

| -25 | -30 | -35 | -40 | -45 | -50 | -55 | -60 | -65 | -70 | |||

| 4VDS-12.2 | 30 | Qo | 19480 | 16830 | 14270 | 11850 | 9640 | 7670 | 5980 | 4560 | 3400 | 2490 |

| Pe | 9.74 | 9.06 | 8.35 | 7.61 | 6.85 | 6.10 | 5.35 | 4.62 | 3.92 | 3.27 | ||

| 40 | Qo | 18910 | 16220 | 13680 | 11330 | 9220 | 7360 | 5760 | 4390 | 3250 | ||

| Pe | 11.05 | 10.23 | 9.37 | 8.49 | 7.60 | 6.72 | 5.85 | 5.01 | 4.22 | |||

| 50 | Qo | 18060 | 15460 | 13050 | 10840 | 8850 | 7090 | 5530 | 6640 | 4990 | ||

| Pe | 12.32 | 11.40 | 10.44 | 9.44 | 8.42 | 7.41 | 6.41 | 6.40 | 5.49 | |||

| 6WDS-16.2 | 30 | Qo | 27600 | 23700 | 20100 | 16800 | 13750 | 11200 | 8650 | 6640 | 4990 | 3660 |

| Pe | 14.13 | 12.93 | 11.76 | 10.60 | 9.48 | 8.40 | 7.37 | 6.40 | 5.49 | 4.65 | ||

| 40 | Qo | 26500 | 22800 | 19330 | 16100 | 13170 | 10570 | 8320 | 6400 | 4780 | ||

| Pe | 16.00 | 14.58 | 13.21 | 11.90 | 10.63 | 9.42 | 8.26 | 7.15 | 6.10 | |||

| 50 | Qo | 25500 | 21900 | 18500 | 15430 | 12660 | 10200 | 8010 | ||||

| Pe | 17.83 | 16.23 | 14.68 | 13.20 | 11.78 | 10.41 | 9.10 | |||||

| 6WDS-20.2 | 30 | Qo | 31900 | 27450 | 23300 | 19440 | 15910 | 12760 | 10020 | 7690 | 5770 | 4230 |

| Pe | 16.43 | 15.02 | 13.64 | 12.30 | 11.00 | 9.76 | 8.57 | 7.44 | 6.40 | 5.40 | ||

| 40 | Qo | 30600 | 26350 | 22350 | 18610 | 15230 | 12240 | 9640 | 7420 | 5540 | ||

| Pe | 18.53 | 16.90 | 15.32 | 13.79 | 12.33 | 10.92 | 9.57 | 8.29 | 7.07 | |||

| 50 | Qo | 29350 | 25200 | 21350 | 17810 | 14630 | 11800 | 9280 | ||||

| Pe | 20.63 | 18.79 | 17.01 | 15.30 | 13.65 | 12.07 | 10.55 | |||||

| 6WDS-25.2 | 30 | Qo | 36200 | 31300 | 26600 | 22250 | 18220 | 14620 | 11480 | 8830 | 6630 | 4870 |

| Pe | 18.84 | 17.27 | 15.71 | 14.16 | 12.65 | 11.19 | 9.80 | 8.49 | 7.29 | 6.20 | ||

| 40 | Qo | 34900 | 30100 | 25500 | 21300 | 17420 | 14000 | 11040 | 8500 | 6350 | ||

| Pe | 21.27 | 19.40 | 17.60 | 15.85 | 14.16 | 12.55 | 11.00 | 9.52 | 8.13 | |||

| 50 | Qo | 33450 | 28750 | 24350 | 20350 | 16720 | 13490 | 10620 | ||||

| Pe | 23.71 | 21.58 | 19.35 | 17.56 | 15.67 | 13.85 | 12.10 | |||||

| 6WDS-30.2 | 30 | Qo | 43400 | 37400 | 31750 | 26500 | 21700 | 17420 | 13690 | 10540 | 7920 | 5800 |

| Pe | 22.53 | 20.65 | 18.78 | 16.94 | 15.15 | 13.42 | 11.77 | 10.20 | 8.74 | 7.40 | ||

| 40 | Qo | 41500 | 35700 | 30300 | 25300 | 20700 | 16680 | 13170 | 10150 | 7590 | ||

| Pe | 25.20 | 23.10 | 21.01 | 18.96 | 16.95 | 15.00 | 13.14 | 11.37 | 9.72 | |||

| 50 | Qo | 39500 | 34000 | 28850 | 24100 | 19870 | 16060 | 12650 | ||||

| Pe | 28.07 | 25.69 | 23.33 | 21.01 | 18.75 | 16.57 | 14.49 | |||||

Based on 20℃ suction gas temperature,50Hz,without liquid subcooling.

Additional cooling or limited suction gas temperature.

Additional cooling and CIC system.

It is engineered for ultra-low temperature refrigeration scenarios, covering -45℃ to -70℃. Key applicable industries include:

Pharmaceutical ultra-low temperature storage (e.g., storing COVID-19 vaccines, influenza biologics, and protein-based pharmaceuticals).

Seafood deep-freezing & export (e.g., flash-freezing high-value products like fresh shrimp, scallops, and premium fish).

Industrial deep-cold raw material storage (e.g., preserving rubber compounds, metal powders, and chemical raw materials).

The double-stage compression technology delivers three core advantages:

Lower energy consumption: It cuts energy use by 18% compared to single-stage compressors of the same power.

Reduced discharge temperature: The discharge temperature is controlled to ≤85℃ (at -35℃ evaporation), preventing thermal damage to temperature-sensitive materials (e.g., pharmaceutical active ingredients).

Less wear & longer lifespan: Intermediate pressure is stabilized at 0.32 MPa, reducing valve wear by 40% and extending component durability.

Warranty: A 2-year comprehensive warranty covers the entire unit (including motor, compressor body, and valves); critical components like the crankshaft and piston rings receive an extended 5-year warranty.

After-sales support:

Global spare parts network (warehouses in the USA, Germany, Singapore) ensures spare parts delivery within 3–5 business days.

24/7 online technical support (resolves 80% of issues within 1 hour) and on-site guidance for large-scale projects (e.g., 500+m³ cold storage).

Customized maintenance plans (quarterly/annual) based on operating hours and application scenarios.