close

Choose Your Site

Global

Social Media

| Horse Power: | |

|---|---|

| Color: | |

| Power supply: | |

| Lubricant: | |

| Availability: | |

| Quantity: | |

2YD/2YG

DMZL

The DMZL 4-Cylinder Low/Mid-Temp Semi-Hermetic Piston Compressor (8-20HP) is engineered for medium-scale refrigeration demands, operating at -15℃ to 12.5℃. It delivers high cooling capacity, stable 24/7 operation, and long service life, making it ideal for dairy storage facilities, industrial process cooling systems, and medium-sized food warehouses. The compressor’s forced-lubrication system and reinforced components ensure reliability in heavy-duty applications, while its energy efficiency helps customers reduce operational costs.

Dairy farms, processing plants, and distributors require 100-200 m³ storage rooms to keep milk, yogurt, cheese, and butter at 2-4℃— a temperature range that preserves freshness and prevents bacterial growth. This compressor maintains this temperature with a variation of ≤1℃, ensuring dairy products meet food safety standards (e.g., FDA, EU 10/2011). Its high cooling capacity (up to 24,300 W@-15℃/30℃) also allows quick cooling of freshly produced dairy, reducing the risk of spoilage.

In manufacturing industries— such as plastic injection molding, metalworking, and electronics production— equipment generates significant heat that can damage tools and reduce product quality. This compressor integrates with process cooling systems to cool hydraulic oil and process fluids from 40℃ to 15℃. This reduces equipment downtime by 20% and extends the life of cutting tools and molds by 30%, lowering production costs for manufacturers.

Grocery chains and food distributors operate 150-300 m³ warehouses to store frozen food (e.g., pizza, frozen meals, and pre-packaged vegetables) at -18℃. This compressor’s forced-lubrication system ensures reliable operation in 24/7 duty cycles, while its hermetic structure resists dust and debris— common in warehouse environments. Its compatibility with R404A (a widely used refrigerant for low-temperature applications) also makes it easy to integrate with existing warehouse refrigeration systems.

• Efficient Valve Plate Assembly: The valve plates use imported spring steel from Germany, with an optimized shape that improves airflow by 15% compared to standard valves. This boosts cooling capacity and reduces energy consumption, making the compressor more efficient in heavy-duty operation.

• Forced-Lubrication System: A dedicated oil pump delivers oil to critical components (bearings, pistons, crankshaft) at a constant pressure of 0.2 MPa. This ensures consistent lubrication even at high loads (up to 20HP), reducing friction and extending component life.

• Built-In Crankcase Heater: A 140W 220V heater prevents refrigerant condensation in the crankcase during shutdown. This protects the motor from damage caused by liquid refrigerant entering the cylinders, a common issue in low-temperature compressors.

• Hardened Steel Crankshaft: The crankshaft is manufactured via forged steel processing and heat-treated to HRC 60-62. It can withstand high torque (up to 50 N·m) in continuous operation, reducing the risk of bending or breaking under heavy loads.

• Chrome-Plated Piston Rings: The piston rings are chrome-plated to enhance wear resistance, making them suitable for use with R404A and R507A— refrigerants that can cause accelerated wear in uncoated rings. This extends the compressor’s service life to 9,000+ operating hours.

• Reinforced Valve Plates: Made from high-strength alloy steel (40Cr), the valve plates can withstand pressure up to 1.0 MPa. They also resist deformation at high temperatures (up to 120℃), ensuring consistent performance in extreme operating conditions.

• On-Site Installation & Commissioning: For large-scale projects (e.g., 200 m³ dairy warehouses), our certified engineers provide on-site installation and commissioning. They ensure the compressor is integrated correctly with the refrigeration system and performs to specifications.

• Remote Diagnostic Tools: The compressor can be equipped with Bluetooth-enabled sensors that transmit real-time data (temperature, pressure, current) to a mobile app. Our technical team can remotely analyze this data to identify potential issues— such as rising oil temperature— before they cause downtime.

• Global Spare Parts Delivery: Critical components like crankshafts, valve plates, and motor windings are stocked in our global warehouses, ensuring delivery within 3-5 business days to most regions.

• Annual Maintenance Contracts: We offer annual maintenance contracts that include oil analysis (to detect contamination), leak detection (using ultrasonic tools), and performance testing. These contracts help customers proactively maintain their compressors and extend their service life.

• Comprehensive Warranty: A 2-year comprehensive warranty covers all components except wear parts (e.g., piston rings, oil filters). This provides customers with long-term protection against manufacturing defects.

• Global Certification Compliance: The compressor meets international standards, including CE (Europe), UL (North America), and ISO 9001. This ensures it can be used in 50+ countries without regulatory issues, simplifying global exports for customers.

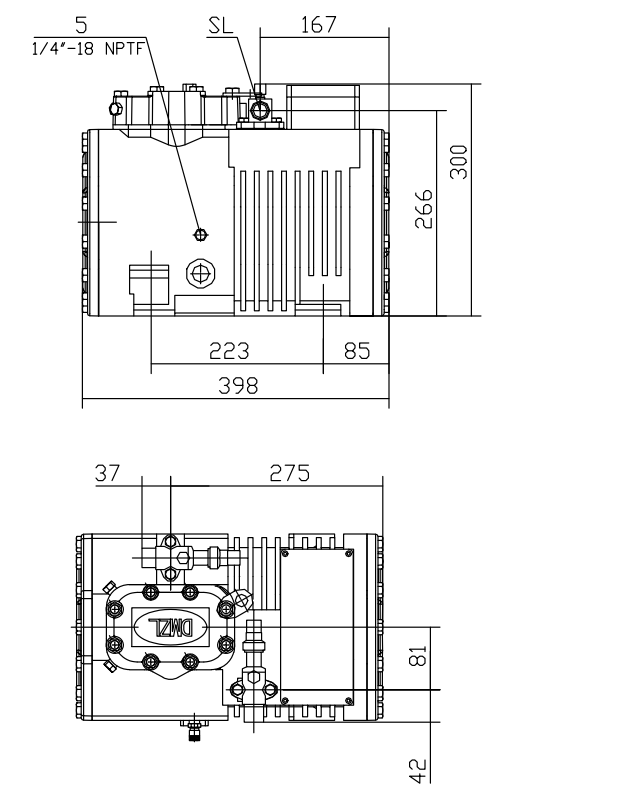

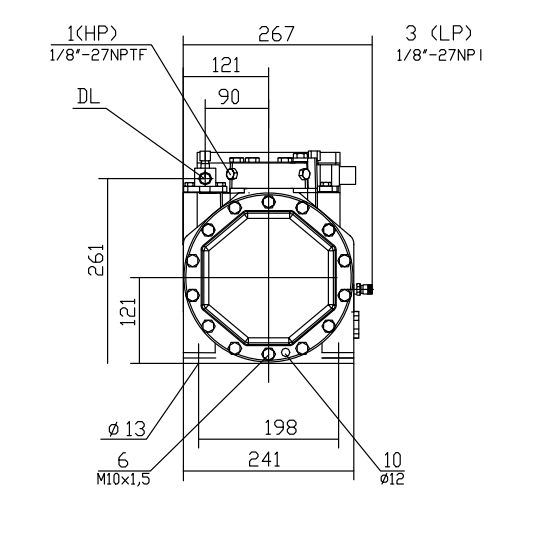

| DMZL Model | Nominal Power HP/KW | Displacement m³/h@ 50Hz | Number of Cylinders×Diameter×Stoke | Exhaust & Suction Valve mm/IN | Oil Volume L | Power V/φ/Hz | Electrical Parameter | Crankcase Heater (220V)W | Oil Supply Method | Weight (with lubricant) Kg | ||

| DL Exhaust Valve | SL Suction Valve | Max Operating Current (A) | Starting/ Locked Current (A) | |||||||||

| 2YD-2.2 | 2/1.5 | 13.4 | 2×Φ50×39.3 | φ16 | φ22 | 1.5 | 220-240△/380-420Y/3/50 265-290△/440-480Y/3/60 | 11.9/6.9 | 53.7/30.7 | 120 | Centrifugal lubrication | 67.5 |

| 2YG-3.2 | 3/2.2 | 13.4 | 2×Φ50×39.3 | φ16 | φ22 | 1.5 | 13.5/7.8 | 64/37 | 120 | 70.5 | ||

| 2YD-3.2 | 3/2.2 | 16.2 | 2×Φ55×39.3 | φ16 | φ22 | 1.5 | 14.8/8.5 | 64/37 | 120 | 70 | ||

| 2YG-4.2 | 4/3 | 16.2 | 2×Φ55×39.3 | φ16 | φ22 | 1.5 | 16.4/9.4 | 76.6/44.2 | 120 | 70 | ||

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | ||||||||||||||||||||||

| Evaporating Temperature ℃ | ||||||||||||||||||||||||

| 12.5 | 10 | 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | ||||||||||||||

| 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | |||

| 2YD-2.2 | 30 | Qo | 11730 | 14076 | 10680 | 12816 | 9710 | 11652 | 8810 | 10572 | 7200 | 8640 | 5820 | 6984 | 4650 | 5580 | 3660 | 4392 | 2820 | 3384 | 2120 | 2544 | 1540 | 1848 |

| Pe | 1.82 | 2.184 | 1.79 | 2.148 | 1.75 | 2.1 | 1.71 | 2.052 | 1.63 | 1.956 | 1.53 | 1.836 | 1.43 | 1.716 | 1.31 | 1.572 | 1.18 | 1.416 | 1.03 | 1.236 | 0.87 | 1.044 | ||

| 40 | Qo | 10320 | 12384 | 9390 | 11268 | 8530 | 10236 | 7730 | 9276 | 6300 | 7560 | 5070 | 6084 | 4030 | 4836 | 3140 | 3768 | 2390 | 2868 | 1760 | 2112 | 1240 | 1488 | |

| Pe | 2.15 | 2.58 | 2.11 | 2.532 | 2.06 | 2.472 | 2.01 | 2.412 | 1.89 | 2.268 | 1.76 | 2.112 | 1.62 | 1.944 | 1.46 | 1.752 | 1.28 | 1.536 | 1.09 | 1.308 | 0.88 | 1.056 | ||

| 50 | Qo | 8950 | 10740 | 8150 | 9780 | 7390 | 8868 | 6690 | 8028 | 5440 | 6528 | 4360 | 5232 | 3440 | 4128 | 2660 | 3192 | 1990 | 2388 | 1430 | 1716 | 970 | 1164 | |

| Pe | 2.47 | 2.964 | 2.41 | 2.892 | 2.35 | 2.82 | 2.28 | 2.736 | 2.13 | 2.556 | 1.96 | 2.352 | 1.78 | 2.136 | 1.58 | 1.896 | 1.36 | 1.632 | 1.12 | 1.344 | 0.86 | 1.032 | ||

| 2YG-3.2 | 50 | Qo | 8930 | 10716 | 8120 | 9744 | 7370 | 8844 | 6670 | 8004 | 5420 | 6504 | 4350 | 5220 | 3430 | 4116 | 2650 | 3180 | 1990 | 2388 | ||||

| Pe | 2.41 | 2.892 | 2.35 | 2.82 | 2.29 | 2.748 | 2.22 | 2.664 | 2.07 | 2.484 | 1.91 | 2.292 | 1.74 | 2.088 | 1.54 | 1.848 | 1.33 | 1.596 | ||||||

| 60 | Qo | 7670 | 9204 | 6980 | 8376 | 6320 | 7584 | 5720 | 6864 | 4630 | 5556 | 3700 | 4440 | 2890 | 3468 | 2210 | 2652 | 1630 | 1956 | |||||

| Pe | 2.70 | 3.24 | 2.62 | 3.144 | 2.54 | 3.048 | 2.46 | 2.952 | 2.28 | 2.736 | 2.09 | 2.508 | 1.87 | 2.244 | 1.64 | 1.968 | 1.38 | 1.656 | ||||||

| 70 | Qo | 6460 | 7752 | 5860 | 7032 | 5310 | 6372 | 4800 | 5760 | 3870 | 4644 | 3070 | 3684 | 2390 | 2868 | 1810 | 2172 | 1310 | 1572 | |||||

| Pe | 3.00 | 3.6 | 2.90 | 3.48 | 2.80 | 3.36 | 2.70 | 3.24 | 2.49 | 2.988 | 2.25 | 2.7 | 2.00 | 2.4 | 1.71 | 2.052 | 1.41 | 1.692 | ||||||

| 2YD-3.2 | 30 | Qo | 14820 | 17784 | 13510 | 16212 | 12290 | 14748 | 11150 | 13380 | 9130 | 10956 | 7400 | 8880 | 5920 | 7104 | 4670 | 5604 | 3610 | 4332 | 2720 | 3264 | 1980 | 2376 |

| Pe | 2.19 | 2.628 | 2.15 | 2.58 | 2.11 | 2.532 | 2.06 | 2.472 | 1.95 | 2.34 | 1.83 | 2.196 | 1.69 | 2.028 | 1.54 | 1.848 | 1.37 | 1.644 | 1.19 | 1.428 | 1.00 | 1.2 | ||

| 40 | Qo | 13050 | 15660 | 11880 | 14256 | 10800 | 12960 | 9790 | 11748 | 8000 | 9600 | 6450 | 7740 | 5130 | 6156 | 4010 | 4812 | 3070 | 3684 | 2270 | 2724 | 1610 | 1932 | |

| Pe | 2.62 | 3.144 | 2.56 | 3.072 | 2.50 | 3 | 2.43 | 2.916 | 2.27 | 2.724 | 2.11 | 2.532 | 1.92 | 2.304 | 1.72 | 2.064 | 1.50 | 1.8 | 1.27 | 1.524 | 1.03 | 1.236 | ||

| 50 | Qo | 11340 | 13608 | 10320 | 12384 | 9370 | 11244 | 8490 | 10188 | 6910 | 8292 | 5550 | 6660 | 4390 | 5268 | 3400 | 4080 | 2570 | 3084 | 1860 | 2232 | 1280 | 1536 | |

| Pe | 302 | 362.4 | 2.94 | 3.528 | 2.85 | 3.42 | 2.76 | 3.312 | 2.56 | 3.072 | 2.35 | 2.82 | 2.11 | 2.532 | 1.86 | 2.232 | 1.60 | 1.92 | 1.32 | 1.584 | 1.02 | 1.224 | ||

| 2YG-4.2 | 50 | Qo | 11300 | 13560 | 10280 | 12336 | 9340 | 11208 | 8460 | 10152 | 6890 | 8268 | 5540 | 6648 | 4380 | 5256 | 3400 | 4080 | 2570 | 3084 | ||||

| Pe | 3.03 | 3.636 | 2.95 | 3.54 | 2.86 | 3.432 | 2.76 | 3.312 | 2.56 | 3.072 | 2.34 | 2.808 | 2.10 | 2.52 | 1.85 | 2.22 | 1.58 | 1.896 | ||||||

| 60 | Qo | 6960 | 8352 | 8810 | 10572 | 8000 | 9600 | 7230 | 8676 | 5870 | 7044 | 4690 | 5628 | 3680 | 4416 | 2830 | 3396 | 2100 | 2520 | |||||

| Pe | 3.39 | 4.068 | 3.28 | 3.936 | 3.17 | 3.804 | 3.06 | 3.672 | 2.81 | 3.372 | 2.54 | 3.048 | 2.26 | 2.712 | 1.96 | 2.352 | 1.65 | 1.98 | ||||||

| 70 | Qo | 8140 | 9768 | 7390 | 8868 | 6700 | 8040 | 6050 | 7260 | 4890 | 5868 | 3890 | 4668 | 3040 | 3648 | 2310 | 2772 | 1700 | 2040 | |||||

| Pe | 3.75 | 4.5 | 3.61 | 4.332 | 3.48 | 4.176 | 3.34 | 4.008 | 3.04 | 3.648 | 2.73 | 3.276 | 2.40 | 2.88 | 2.06 | 2.472 | 1.70 | 2.04 | ||||||

Suction gas temperature 20℃,50Hz,without liquid subcooling.

Additional cooling or limited suction gas temperature.

R404A/R507A

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | ||||||||||||

| Evaporating Temperature ℃ | ||||||||||||||

| 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| 2YD-2.2 | 30 | Qo | 10110 | 8340 | 6810 | 5490 | 4360 | 3390 | 2570 | 1880 | 1300 | |||

| Pe | 2.72 | 2.59 | 2.43 | 2.25 | 2.05 | 1.83 | 1.59 | 1.35 | 1.09 | |||||

| 40 | Qo | 8490 | 68980 | 5670 | 4530 | 3560 | 2720 | 2020 | 1420 | 920 | ||||

| Pe | 3.15 | 2.94 | 2.7 | 2.44 | 2.17 | 1.88 | 1.58 | 1.28 | 0.98 | |||||

| 50 | Qo | 6900 | 5640 | 4550 | 3600 | 2780 | 2080 | 1490 | 990 | |||||

| Pe | 3.55 | 3.25 | 2.93 | 2.59 | 2.25 | 1.9 | 1.54 | 1.19 | ||||||

| 2YG-3.2 | 30 | Qo | 15940 | 14630 | 12260 | 10200 | 8420 | 6870 | 5540 | 4400 | 3420 | 2590 | 1890 | |

| Pe | 2.79 | 2.8 | 2.77 | 2.71 | 2.6 | 2.45 | 2.28 | 2.08 | 1.86 | 1.62 | 1.37 | |||

| 40 | Qo | 13510 | 12390 | 10380 | 8610 | 7080 | 5750 | 4600 | 3610 | 2760 | 2040 | 1430 | ||

| Pe | 3.49 | 3.44 | 3.32 | 3.16 | 2.96 | 2.74 | 2.49 | 2.21 | 1.92 | 1.62 | 1.31 | |||

| 50 | Qo | 11110 | 10180 | 8500 | 7030 | 5740 | 4630 | 3660 | 2820 | 2110 | 1510 | 1000 | ||

| Pe | 4.11 | 4.02 | 3.8 | 3.55 | 3.27 | 2.96 | 2.63 | 2.29 | 1.93 | 1.57 | 1.2 | |||

| 2YD-3.2 | 30 | Qo | 12470 | 10290 | 8400 | 6780 | 5380 | 4190 | 3180 | 2330 | 1630 | |||

| Pe | 3.33 | 3.15 | 2.95 | 2.72 | 2.48 | 2.21 | 1.93 | 1.64 | 1.35 | |||||

| 40 | Qo | 10510 | 8650 | 7040 | 5640 | 4440 | 3420 | 2550 | 1810 | 1200 | ||||

| Pe | 3.85 | 3.58 | 3.29 | 2.98 | 2.65 | 2.32 | 1.97 | 1.62 | 1.27 | |||||

| 50 | Qo | 8590 | 7050 | 5710 | 4550 | 3540 | 2690 | 1950 | 1340 | |||||

| Pe | 4.35 | 3.98 | 3.60 | 3.21 | 2.80 | 2.39 | 1.98 | 1.57 | ||||||

| 2YG-4.2 | 30 | Qo | 19440 | 17840 | 14960 | 12450 | 10280 | 8400 | 6770 | 5380 | 4190 | 3170 | 2320 | |

| Pe | 3.48 | 3.48 | 3.42 | 3.32 | 3.17 | 2.98 | 2.76 | 2.50 | 2.23 | 1.94 | 1.64 | |||

| 40 | Qo | 16470 | 15110 | 12660 | 10520 | 8660 | 7050 | 5650 | 4450 | 3420 | 2540 | 1810 | ||

| Pe | 4.31 | 4.25 | 4.08 | 3.86 | 3.61 | 3.33 | 3.02 | 2.69 | 2.34 | 1.98 | 1.61 | |||

| 50 | Qo | 13550 | 12430 | 10400 | 8620 | 7070 | 5720 | 4550 | 3540 | 2690 | 1960 | 1340 | ||

| Pe | 5.08 | 4.96 | 4.68 | 4.36 | 4.01 | 3.63 | 3.23 | 2.82 | 2.40 | 1.98 | 1.55 | |||

Based on 20℃ suction gas temperature,50Hz,without liquid subcooling.

Additional cooling or limited suction gas temperature.

Additional cooling and CIC system.

It is compatible with four refrigerants: R404A, R22, R134A, and R507C. This compatibility allows flexible integration with different refrigeration systems, such as low-temperature frozen food storage (R404A) and general cooling applications (R22/R134A).

The compressor offers three HP options, with specific models matching each:

• 2HP: Model 2YD-2.2 (nominal power: 2HP/1.5KW)

• 3HP: Models 2YG-3.2 and 2YD-3.2 (nominal power: 3HP/2.2KW)

• 4HP: Model 2YG-4.2 (nominal power: 4HP/3KW)

It is designed for three core scenarios:

• Dairy product refrigeration: Maintains 2–4℃ (temperature variation ≤1℃) in 100–200 m³ storage rooms, complying with standards like FDA and EU 10/2011 to preserve milk, yogurt, and cheese.

• Industrial process cooling: Cools hydraulic oil and process fluids from 40℃ to 15℃ for plastic injection molding, metalworking, and electronics production—reducing equipment downtime by 20% and extending tool life by 30%.

• Medium food warehouses (150–300 m³): Operates 24/7 to keep frozen food (e.g., pizza, pre-packaged vegetables) at -18℃, with dust-resistant hermetic structure and R404A compatibility.

Three critical design features ensure efficiency and reliability:

• Efficient Valve Plate Assembly: Uses German imported spring steel, optimizing airflow by 15% to boost cooling capacity and reduce energy use.

• Forced-Lubrication System: A dedicated oil pump delivers oil to bearings, pistons, and crankshafts at a constant 0.2 MPa—ensuring stable lubrication even at high loads (up to 20HP) and reducing friction.

• Built-In Crankcase Heater: A 140W 220V heater prevents refrigerant condensation in the crankcase during shutdown, protecting the motor from liquid refrigerant damage.