Selecting a reliable semi-hermetic compressor manufacturer shapes a company’s bottom line and long-term stability. Consistent product quality, advanced technology, and transparent maintenance standards signal true dependability. For example, energy-efficient compressors with variable speed drives can lower energy costs by up to 35%, while heat recovery systems may save over $30,000 annually and reduce CO₂ emissions. Companies that choose poorly often face frequent breakdowns, wasted energy, and rising expenses, but those who partner with trusted suppliers secure significant operational and financial advantages.

Key Takeaways

- Look for manufacturers with recognized quality certifications like ISO9001 to ensure consistent product quality and traceability.

- Choose compressors compatible with low-GWP refrigerants to meet environmental regulations and reduce carbon emissions.

- Reliable manufacturers use advanced technologies such as variable frequency drives and IoT for better energy efficiency and predictive maintenance.

- Check for transparent quality assurance processes and access to detailed manufacturing records to build trust in product reliability.

- Consider manufacturers with strong customer support, including clear warranties, fast spare parts delivery, and expert technical guidance.

- Partner with suppliers who offer efficient logistics, real-time order tracking, and global shipping to ensure timely delivery.

- Review customer testimonials, industry awards, and case studies to verify a manufacturer’s reputation and real-world performance.

- Opt for manufacturers that provide customization options and continuous improvement to meet your specific application needs.

Certifications and Compliance for Semi-Hermetic Compressor Manufacturers

Recognized Quality Certifications

ISO9001 and ISO9001-2016 Standards

Manufacturers that hold ISO9001 and ISO9001-2016 certifications demonstrate a strong commitment to quality management. These standards require companies to establish clear processes, monitor performance, and continually improve their operations. When a manufacturer meets these requirements, customers gain confidence in the consistency and reliability of each semi-hermetic compressor produced. ISO-certified companies often maintain detailed records, which help ensure traceability and accountability throughout the manufacturing process.

Third-Party Audits and Documentation

Third-party audits play a crucial role in verifying a manufacturer’s compliance with international standards. Independent auditors review documentation, inspect production lines, and assess quality control systems. This external validation helps buyers identify manufacturers who consistently meet or exceed industry benchmarks. Reliable suppliers provide transparent audit reports and make documentation available upon request, supporting informed purchasing decisions.

Regulatory and Environmental Compliance

Low-GWP Refrigerant Compatibility

Modern semi-hermetic compressors must support low-global warming potential (GWP) refrigerants to comply with evolving environmental regulations. Manufacturers now design compressors compatible with eco-friendly refrigerants such as R-290 (propane) and R-744 (CO₂). These refrigerants reduce environmental impact and align with global efforts to lower carbon emissions. Companies also invest in energy-saving technologies, including variable speed drives and IoT-enabled systems, to further improve efficiency and sustainability.

Tip: Choosing compressors with low-GWP refrigerant compatibility not only ensures regulatory compliance but also positions businesses for future market demands.

Adherence to Kyoto Protocol and EU F-Gas Regulation

Leading manufacturers align their products with international agreements like the Kyoto Protocol and the EU F-Gas Regulation. These regulations aim to phase out high-GWP refrigerants and promote sustainable refrigeration practices. In response, manufacturers have shifted toward natural and low-GWP refrigerants, modernized their production processes, and adopted environmentally friendly lubricants. This proactive approach supports global sustainability goals and helps customers avoid costly regulatory penalties.

- Manufacturers use recyclable materials in compressor construction.

- They develop environmentally friendly lubricants and implement eco-friendly manufacturing processes.

- Many explore bio-based or recycled materials for components.

- Companies focus on improving energy efficiency, often achieving higher coefficient of performance (COP) values.

- Adoption of energy-efficient designs is driven by strict environmental regulations, especially in North America and Europe.

- The industry aligns with global efforts to reduce carbon footprint and support food safety through reliable temperature control.

Product Testing and Traceability

Quality Assurance Processes

Quality assurance forms the backbone of any reputable manufacturing operation. Manufacturers implement rigorous testing protocols at every stage of production. These protocols include performance tests, leak detection, and durability assessments. By maintaining strict quality controls, companies ensure that each compressor meets safety and efficiency standards before reaching the customer.

Transparent Manufacturing Records

Transparency in manufacturing records allows customers to trace the origin and history of each product. Reliable manufacturers provide access to detailed production logs, test results, and compliance certificates. This openness builds trust and enables buyers to verify that each semi-hermetic compressor meets both regulatory and operational requirements.

- Manufacturers adopt low-GWP refrigerants and comply with stricter environmental norms, especially in Europe and North America.

- They integrate energy-saving technologies and invest in research and development to produce quieter, more efficient compressors.

- Government regulations and incentives drive the use of eco-friendly refrigerants and accelerate market growth.

- The industry implements stringent regulations to phase out high-GWP refrigerants and supports the transition to sustainable solutions.

Manufacturing Capabilities and Technological Innovation in Semi-Hermetic Compressors

Advanced Production Facilities

PLC Controllers and Variable Frequency Drives

Modern compressor manufacturers invest in advanced production facilities that feature programmable logic controllers (PLCs) and variable frequency drives (VFDs). PLCs automate complex processes, improving precision and reducing human error. VFDs allow compressors to adjust motor speed based on demand, which increases energy efficiency and extends equipment life. These technologies help manufacturers deliver compressors that meet strict performance and reliability standards.

IoT and Industry 4.0 Integration

Industry leaders now integrate Internet of Things (IoT) technology and Industry 4.0 principles into their operations. IoT sensors monitor pressure, flow, and energy consumption in real time, providing actionable insights for system optimization. Digital twin technology and predictive maintenance tools enable real-time performance monitoring and early detection of potential issues. This approach reduces downtime and maintenance costs, with some case studies reporting up to a 25% reduction in maintenance expenses and efficiency gains of 10%.

Note: Manufacturers also use lightweight materials like titanium and carbon composites, additive manufacturing (3D printing), and advanced impeller designs to further boost efficiency and flexibility.

- Manufacturers adopt digitalization through IIoT sensors and predictive maintenance programs.

- Efficiency gains range from 2% to 15%, with energy recovery systems contributing an additional 5-15%.

- Intelligent alarms and controls prevent overheating and optimize compressed air costs.

Continuous Improvement and Customization

Oil-Free and Energy-Efficient Designs

Continuous improvement drives innovation in compressor design. Oil-free centrifugal compressors with frictionless bearing technology now offer reliable, energy-efficient solutions for large chillers and heat recovery systems. A ten-year study on oil-free semi-hermetic compressors in data centers showed that these units maintained original performance levels, while traditional oil-lubricated compressors lost up to 30% efficiency due to oil fouling and wear. This demonstrates the long-term value of advanced, oil-free designs.

OEM/ODM and Flexible Product Options

Manufacturers provide Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services to meet diverse customer needs. Flexible product options allow clients to specify features such as refrigerant compatibility, noise levels, and energy efficiency. Companies like Apple and General Electric use iterative design and Lean Manufacturing to refine products and reduce defects, while others like Nestlé have improved production efficiency by 35% and reduced energy use by 25%. These examples highlight the benefits of continuous improvement and customization in manufacturing.

| Company | Key Manufacturing Improvements |

|---|---|

| Boeing | Assembly time down 61%, defect rates down 65%, inventory down 55% |

| Toyota | Vehicle completion every 55 seconds, quality above 99% |

| Harley-Davidson | Production time cut by 60%, labor efficiency up 80% |

| Nestlé | Efficiency up 35%, energy use down 25%, water use down 40% |

Production Scale and Consistency

Handling Large-Scale Orders

Reliable manufacturers demonstrate their capabilities by serving diverse sectors such as petrochemical, pharmaceutical, food and beverage, and HVAC. They handle large-scale orders and adapt to regional market demands, ensuring timely delivery and consistent product quality.

Economies of Scale and Consistent Quality

Manufacturers leverage economies of scale to offer competitive pricing and maintain high standards. Global service networks and outcome-based maintenance contracts guarantee uptime and performance. Strategic partnerships with IoT and predictive analytics providers have reduced unplanned downtime by up to 30%. The introduction of advanced models, such as variable-speed semi-hermetic compressors with digital monitoring, supports consistent performance across multiple applications.

- Consistent performance under varying load conditions ensures reliability for industrial clients.

- Regional players focus on niche segments, demonstrating both depth and breadth in production scale.

Track Record, Reputation, and Real-World Performance

Customer Reviews and Industry Recognition

Online Ratings and Testimonials

Customers often share their experiences with compressor manufacturers through online ratings and testimonials. These reviews provide valuable insights into product reliability, customer service, and long-term satisfaction. Many buyers highlight consistent performance and responsive support as key reasons for their loyalty. Positive feedback on platforms such as industry forums and procurement websites signals a manufacturer’s commitment to quality. Companies with high ratings tend to attract repeat business and build strong reputations in the market.

Industry Awards and Certifications

Industry organizations recognize manufacturers that demonstrate excellence in innovation, safety, and sustainability. Awards from groups like the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) or the European Association of Refrigeration (AREA) validate a company’s achievements. Certifications for environmental stewardship and product safety further reinforce credibility. Manufacturers that receive these honors often lead the way in adopting new technologies and setting industry standards.

Case Studies and Measurable Outcomes

Cost Savings and Efficiency Improvements

Real-world case studies reveal the tangible benefits of advanced compressor solutions. For example, OSCO Controls upgraded a natural gas compression control panel, resulting in measurable improvements. The new system optimized engine RPM and compression rates, which reduced emissions and maintenance needs. These changes led to significant cost savings and less downtime. The table below summarizes the key outcomes:

| Metric/Outcome | Description |

|---|---|

| Annual Energy Cost Savings | $118,000 per year through master control system implementation |

| Monthly Savings | Over $10,000 per month, exceeding projections |

| System Improvements | Optimized compressor load sharing and lowered system pressure |

| Operational Benefits | More consistent plant pressure at steady 100 psig, leading to reliable production |

| Monitoring Enhancements | Added instrumentation for continuous KPI trending (temperature, pressure, flow, dew point) |

These results show how automation and control upgrades can deliver strong returns on investment for compressor users.

Downtime Reduction and Capacity Gains

Manufacturers with a proven track record often help clients reduce downtime and increase capacity. By implementing predictive maintenance and advanced monitoring, companies report fewer unexpected failures. Plants experience more stable operations and higher output. Reliable semi-hermetic compressor solutions contribute to these improvements by maintaining steady performance under demanding conditions.

Sector-Specific Success Stories

Mining, Manufacturing, Food Processing, Pharmaceuticals

In mining, manufacturers supply compressors that withstand harsh environments and heavy loads. Manufacturing plants benefit from energy-efficient models that lower operating costs. Food processing facilities rely on precise temperature control to ensure product safety. Pharmaceutical companies require strict compliance with quality standards, and leading manufacturers deliver compressors that meet these needs.

Oil & Gas Industry Growth and Adoption

The oil and gas sector has seen rapid adoption of advanced compressor technologies. Companies in this industry demand robust equipment that can handle continuous operation and fluctuating pressures. Manufacturers with a strong reputation provide solutions that support growth and improve operational efficiency across global projects.

Customer Support and Service for Semi-Hermetic Compressor Buyers

Pre-Sales Consultation and Expert Guidance

Needs Assessment and Sizing Recommendations

Reliable manufacturers begin their customer journey with thorough needs assessments. Their technical teams analyze operational requirements, facility size, and environmental conditions. This process ensures that buyers receive accurate sizing recommendations for their equipment. Proper sizing prevents energy waste and reduces the risk of premature wear. Many manufacturers use digital tools and site surveys to collect data, which leads to more precise recommendations.

Application-Specific Advice

Expert guidance extends beyond sizing. Manufacturers provide tailored advice based on the buyer’s industry, whether it involves food processing, pharmaceuticals, or mining. They consider factors such as refrigerant compatibility, noise restrictions, and energy efficiency targets. This level of consultation helps buyers select the most suitable semi-hermetic compressor for their unique applications.

Tip: Early engagement with technical experts can prevent costly mistakes and ensure long-term operational efficiency.

After-Sales Support and Maintenance

Warranty Coverage and Service Agreements

Strong after-sales support starts with clear warranty coverage and flexible service agreements. Leading manufacturers offer comprehensive warranties that cover parts and labor for a defined period. They also provide options for extended service contracts, which include preventive maintenance and emergency repairs. Certain warranty policies enforce strict repair time thresholds. For example, New York’s Lemon laws require repairs within 15 days during the warranty period, or the customer receives a full refund. This approach motivates manufacturers to resolve issues quickly and maintain high service standards.

Spare Parts Availability and Repair Accessibility

Timely access to spare parts and repair services is critical for minimizing downtime. Manufacturers with global service networks maintain well-stocked inventories and deploy skilled technicians. The table below highlights key statistics that reflect the quality of after-sales support in the industry:

| Statistic / Insight | Description | Impact on After-Sales Quality |

|---|---|---|

| 35% reduction in complaint resolution time | IoT-enabled warranty service app integration | Improved responsiveness and customer satisfaction |

| 28% reduction in callback rates | AR-assisted repair estimates | Higher first-time fix rates and repair accuracy |

| 22% increase in daily jobs completed | AI-optimized routing | Faster repairs and greater efficiency |

| 19-point increase in Net Promoter Score | Proactive maintenance suggestions | Enhanced customer loyalty |

| 41% reduction in service disputes | IoT diagnostic tools for transparency | Improved trust in repair process |

These improvements demonstrate how technology and proactive service models enhance the customer experience.

Training and Technical Resources

Installation Guidance and Troubleshooting

Manufacturers support buyers with detailed installation manuals, video tutorials, and on-site training. Their technical teams assist with system setup and initial testing. When issues arise, customers can access troubleshooting guides or contact support hotlines for immediate assistance. This hands-on approach reduces installation errors and accelerates system commissioning.

Ongoing Education and Updates

Continuous education ensures that operators stay informed about the latest maintenance practices and product updates. Manufacturers offer webinars, technical bulletins, and refresher courses. These resources help customers maximize equipment lifespan and maintain compliance with evolving industry standards.

Note: Comprehensive training and accessible resources empower buyers to operate and maintain their semi-hermetic compressor systems with confidence.

Logistics, Trade Advantages, and Accessibility

Efficient Supply Chain and Delivery

Real-Time Tracking and Inventory Management

Reliable semi-hermetic compressor manufacturers invest in advanced supply chain systems. Real-time tracking allows customers to monitor their orders from placement to delivery. Inventory management systems use digital tools to maintain high accuracy rates and prevent stockouts. These practices ensure that customers receive products on time and with minimal errors.

| Metric Name | What It Measures | Example / Calculation | Why It Matters |

|---|---|---|---|

| Average Delivery Time | Time from order to delivery | Order placed Jan 1, delivered Jan 10 → Lead Time = 9 days | Faster delivery improves satisfaction and creates a competitive edge. |

| Inventory Turnover | Frequency inventory is sold and replaced | $500,000 COGS ÷ $100,000 inventory = 5 times/year | High turnover signals efficient inventory management and product availability. |

| Forecast Accuracy | Precision of demand predictions | Forecast 500 units, actual 450 → 88.89% accuracy | Accurate forecasts reduce excess inventory and stockouts, optimizing supply chain performance. |

| Customer Fill Rate | Percentage of orders fulfilled on time | 90 delivered out of 100 ordered = 90% fill rate | High fill rates reflect strong responsiveness and reliable stock levels. |

Note: Manufacturers with high inventory accuracy and short lead times consistently outperform competitors in customer satisfaction.

Partnerships with Global Logistics Providers

Manufacturers form strategic partnerships with global logistics providers to streamline international shipping. These alliances enable real-time shipment tracking, customs clearance support, and reliable last-mile delivery. Customers benefit from reduced transit times and fewer disruptions, even for complex cross-border projects.

Trade Agreements and Cost Benefits

Impact of Free Trade Agreements on Pricing and Customs

Trade agreements play a crucial role in reducing manufacturing expenses and improving pricing structures. When manufacturers operate within regions covered by free trade agreements, they benefit from lower tariffs and simplified customs procedures. A coordinated approach to trade and cost management, such as adopting standardized systems, leads to significant savings and more favorable trade balances. These advantages allow manufacturers to offer competitive pricing and pass cost benefits to customers.

Bulk Discounts and Flexible Shipping Options

Manufacturers often provide bulk order discounts and flexible shipping arrangements. Customers who purchase large quantities receive preferential pricing, which lowers overall procurement costs. Flexible shipping options, including consolidated shipments and expedited delivery, help buyers manage inventory and meet project deadlines efficiently.

Scalability and Global Reach

Support for International Projects

Leading compressor manufacturers support projects across multiple continents. They offer a broad product portfolio, including units for light, medium, and heavy industrial tasks. Portable compressors serve field maintenance needs, while stationary models support large infrastructure projects. Manufacturers adapt to regional requirements, such as energy efficiency mandates in Europe or rapid industrialization in Asia-Pacific.

| Aspect | Details |

|---|---|

| Product Segmentation | Output power ranges from <50 kW to >500 kW, supporting scalability for diverse applications. |

| Deployment Environment | Portable and stationary units address both field and fixed infrastructure needs. |

| Regional Growth Patterns | Americas: Oil & gas, modernization. EMEA: Regulatory retrofits. Asia-Pacific: Industrialization, renewables. |

| Manufacturer Strategies | Broad portfolios, digital platforms, service networks, and local production capacity. |

Consistent Delivery for Large Orders

Manufacturers demonstrate global reach by consistently delivering large orders for international projects. They diversify suppliers and localize production to avoid tariffs and ensure timely fulfillment. In regions like North America and Asia-Pacific, strong OEM relationships and dense service networks support high-volume sales and customization. This approach guarantees that customers receive reliable products, regardless of project size or location.

Tip: Choosing a manufacturer with proven global logistics and scalable production ensures uninterrupted supply for both routine operations and major expansions.

Transparency and Communication with Semi-Hermetic Compressor Manufacturers

Responsiveness and Clarity

Timely Replies to Inquiries

Manufacturers who value transparency respond quickly to customer inquiries. Fast replies show respect for the customer’s time and indicate a well-organized support system. Many leading companies track their average response times and set clear targets, such as replying to social media messages within 24 hours. This approach helps build trust and keeps projects on schedule.

Clear Documentation and Quotations

Clarity in documentation and quotations reduces misunderstandings and supports smooth transactions. Top manufacturers provide detailed, easy-to-read documents that outline product specifications, pricing, and terms. They also make governance documents, such as codes of conduct, accessible on public portals. The table below highlights key transparency metrics that support effective communication:

| Transparency Metric | Description | Example |

|---|---|---|

| Average Response Time | Measures how quickly a company responds to inquiries and complaints. | 24-hour response window for social media inquiries. |

| Documentation Accessibility | Shows how easily stakeholders can access governance documents. | Compliance documents available on public portals. |

| Social Media Engagement | Tracks response rates and sentiment on social platforms. | Maintaining a 24-hour response window for social media. |

| Clarity Scores in Disclosures | Reflects the clearness of sustainability reports and public disclosures. | Clear communication in sustainability reports for stakeholder engagement. |

Open Information Sharing

Access to Product Data and Certifications

Reliable manufacturers share detailed product data and certification information through open platforms. They provide documentation, recorded demonstrations, and public references that align with industry frameworks. A structured, point-based evaluation system ensures that each product meets strict criteria. For example, companies must achieve at least 75% of total criteria points to receive certification. This system covers capabilities such as data ingestion, reporting, and anomaly management, with each capability assigned a specific score.

| Certification Aspect | Description | Evidence Type | Scoring / Weighting |

|---|---|---|---|

| Publicly Referenceable Info | Product features aligned to framework capabilities | Documentation and recorded demo | Weighted tool criteria points |

| Product Demonstration | Video recording showcasing product capabilities | Video demonstration | Binary scoring per criterion |

| Scoring Threshold | Minimum 75% of total criteria points required for certification | Quantitative threshold | Combined score from all criteria |

| Capability Examples | Data ingestion, reporting, anomaly management, planning, etc. | Defined capabilities with assigned points | Points range from 3 to 5 per capability |

Transparent Warranty and Service Policies

Manufacturers who practice transparency publish their warranty and service policies in clear, accessible language. Customers can review these policies before making a purchase, which helps them understand coverage and limitations. This openness reduces disputes and builds long-term confidence in the manufacturer’s support.

Multilingual and Multichannel Support

Support for International Clients

Global manufacturers recognize the importance of supporting customers in their native languages. Research shows that 70% of customers feel more loyal when they receive support in their own language. Multilingual support increases tolerance for product issues and reduces the risk of losing clients. Companies use translation tools, multilingual chatbots, and knowledge bases to improve response times and resolution rates across languages.

- 62% of customers are more tolerant of product issues if support is available in their native language.

- 35% of end users would switch to a product offering native language support.

- Chatbots can triage inquiries in over 38 languages, ensuring faster routing to the right support team.

Availability Across Communication Platforms

Manufacturers offer support through multiple channels, including email, phone, live chat, and social media. This multichannel approach ensures that customers can reach support teams using their preferred method. Automated tools and human agents work together to maintain high response rates and resolution quality, even across different languages. For buyers of Semi-Hermetic Compressor systems, this level of accessibility ensures smooth communication throughout the procurement and operational process.

Real-World Examples and Success Stories in Semi-Hermetic Compressor Procurement

Cost Reduction and Procurement Efficiency

Brazilian Manufacturer’s 35% Cost Savings

A leading manufacturing company in Brazil achieved a remarkable 35% reduction in procurement expenses after switching to a new supplier for their compressor systems. This significant cost saving resulted from improved supplier negotiations, streamlined procurement processes, and the adoption of advanced compressor technologies. The following table highlights cost-saving actions and their additional benefits:

| Improvement Action | Annual Cost Savings | Additional Benefits |

|---|---|---|

| Compressor staging controls (production hours) | $13,277 | Major portion of savings |

| Staging controls (non-production hours) | $2,375 | Additional savings |

| Total annual savings | $15,652 | 138 tonnes CO₂ emissions reduced |

| Installing 30-hp VFD compressor | Not quantified | Improved reliability, energy and cost savings |

These results demonstrate how strategic procurement decisions and technology upgrades can drive both financial and environmental benefits.

Bulk Order Discounts and Lead Time Improvements

Many companies benefit from bulk order discounts and reduced lead times when partnering with reliable compressor manufacturers. For example, a food processing facility in Argentina reported a 20% increase in production efficiency after receiving timely deliveries of pumps and compressors. The ability to process larger orders quickly allows businesses to meet market demand and reduce inventory costs.

Companies that optimize order processing and inventory management often see a 24% reduction in order processing time and a 40% decrease in labor overtime costs.

Operational Efficiency and Downtime Reduction

30% Downtime Reduction in Mining

Mining operations in Chile experienced a 30% reduction in equipment downtime after implementing durable compressor solutions. These improvements resulted from the use of robust semi-hermetic compressor models designed for harsh environments. Enhanced reliability and predictive maintenance tools helped mining companies maintain continuous production and avoid costly interruptions.

20% Efficiency Increase in Food Processing

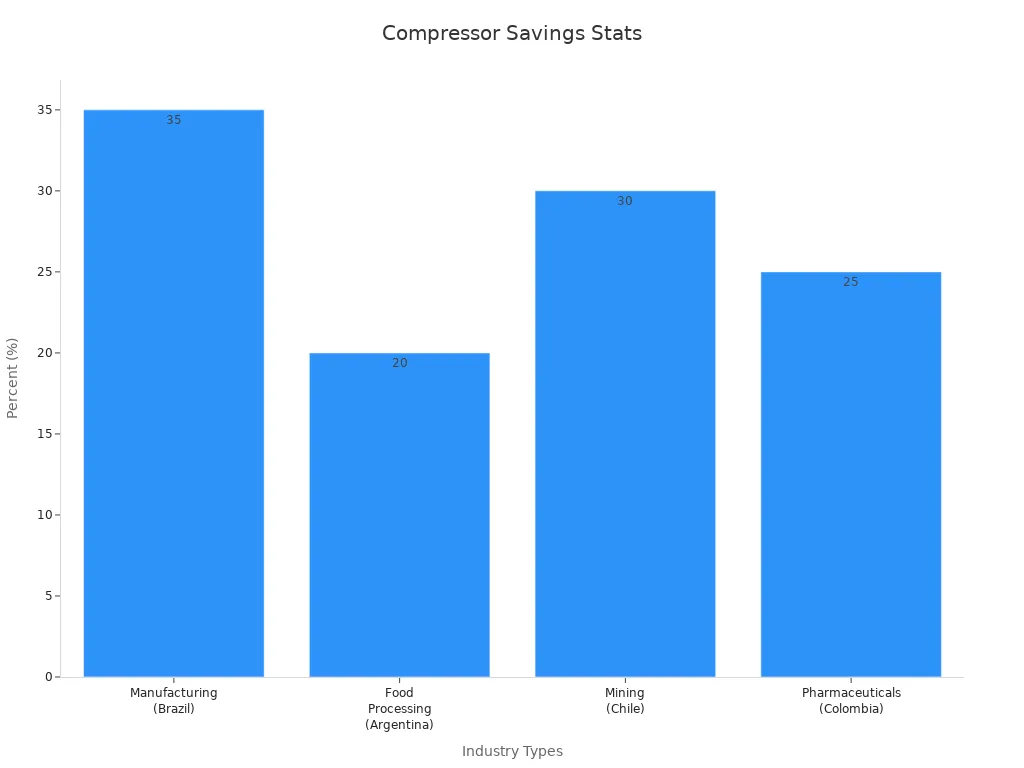

A food processing company in Argentina achieved a 20% efficiency gain by upgrading to advanced compressor systems. Timely equipment delivery and improved system integration played key roles in this success. The following chart illustrates percentage improvements in cost reduction and efficiency across several industries:

Energy and Environmental Impact

31% Energy Savings from Leak Repairs

Leak detection and repair programs deliver substantial energy savings. One facility reported a 31% reduction in energy use after addressing leaks in their compressed air systems. The program cost $2,500 and paid for itself within three months, saving $9,100 annually. These savings also contribute to lower carbon emissions and improved sustainability.

Adoption of Sustainable Refrigeration Solutions

Many companies now adopt sustainable refrigeration solutions by choosing compressors compatible with low-GWP refrigerants. These choices help businesses comply with environmental regulations and reduce their carbon footprint. For example, eliminating nitrogen backup systems led to $8,200 in annual savings and immediate payback, while energy efficiency projects costing $27,800 achieved payback in just 15 months.

Upgrading to modern semi-hermetic compressor systems supports both operational efficiency and environmental responsibility.

Selecting a reliable Semi-Hermetic Compressor manufacturer requires careful evaluation. Companies should benchmark against industry standards, use operational controls, and involve qualified personnel to ensure consistent performance. The following checklist helps buyers identify trustworthy partners:

- Review manufacturer recommendations and industry benchmarks.

- Use operational controls and checklists to monitor performance.

- Confirm the presence of automation systems and skilled operators.

- Regularly update controls to maintain efficiency and compliance.

- Collaborate with service teams to detect and address deviations.

A reliable partnership leads to cost savings, improved efficiency, and long-term business growth.

FAQ

What is a semi-hermetic compressor?

A semi-hermetic compressor features a sealed housing that allows access for maintenance. Technicians can open the casing to repair or replace internal parts. This design increases serviceability and extends equipment lifespan.

How do certifications like ISO9001 benefit buyers?

ISO9001 certification signals that a manufacturer follows strict quality management systems. Buyers gain confidence in product consistency, traceability, and compliance with international standards. This reduces the risk of defects and operational failures.

Why is low-GWP refrigerant compatibility important?

Low-GWP refrigerant compatibility ensures compliance with environmental regulations. Companies using these compressors reduce greenhouse gas emissions and avoid regulatory penalties. This choice also supports long-term sustainability goals.

How can buyers verify a manufacturer’s reputation?

Buyers should review online testimonials, industry awards, and case studies. Reliable manufacturers often share customer success stories and maintain high ratings on procurement platforms. > Tip: Request references from similar industries for added assurance.

What after-sales support should buyers expect?

Buyers should expect clear warranty terms, fast spare parts delivery, and access to technical support. Leading manufacturers provide training resources and proactive maintenance programs to maximize equipment uptime.

Do reliable manufacturers offer customization options?

Yes. Reliable manufacturers provide OEM and ODM services. They tailor compressors for specific refrigerants, noise levels, and energy efficiency requirements. Customization ensures the best fit for unique industrial applications.

How do logistics partnerships impact delivery?

Strong logistics partnerships enable real-time order tracking and efficient global shipping. Customers benefit from shorter lead times, fewer delays, and reliable delivery—even for large or international orders.

Send your message to us:

Post time: Jun-27-2025