close

Choose Your Site

Global

Social Media

| Horse Power: | |

|---|---|

| Power supply: | |

| Energy regulation: | |

| Availability: | |

| Quantity: | |

SLG

RFC

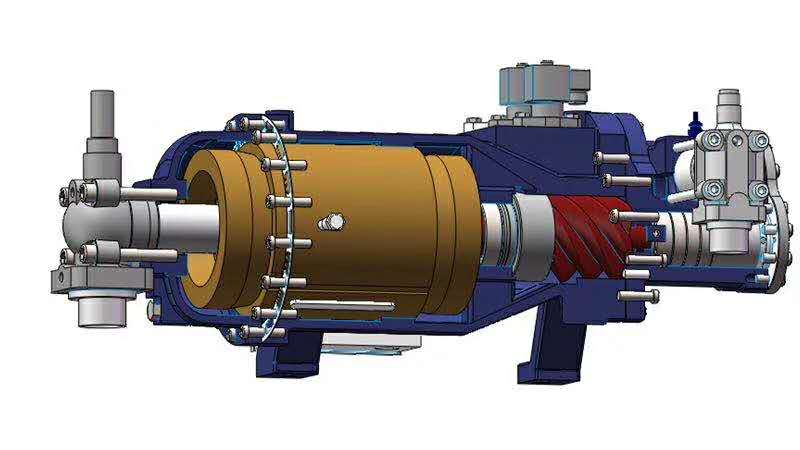

The Semi-Hermetic Screw Compressor MBP (SLG series) fills the gap between fully hermetic and open compressors, offering a balanced solution for medium-power cooling needs (35-220 HP). It addresses industry pain points like high maintenance costs, refrigerant leaks, and inefficient energy use—making it a reliable choice for commercial and industrial cooling systems.

In plastic molding, metal processing, or chemical production lines, 24/7 operation demands minimal downtime. The SLG series’ removable housing allows technicians to access internal components (screws, motor windings) in 30 minutes or less (vs. 2+ hours for sealed hermetic units), reducing production losses caused by compressor failures. Its stable power output also prevents machinery overheating, ensuring consistent product quality.

Maritime environments pose unique challenges: high humidity, salt corrosion, and vibration. The SLG series’ enhanced sealing (superior to open compressors) prevents refrigerant leaks, while its adaptive energy regulation (step/stepless) maintains optimal cooling for cargo—whether preserving seafood at -18°C or pharmaceuticals at 2-8°C during transoceanic voyages.

For high-volume ice production (e.g., concrete cooling, food processing), the SLG series adjusts cooling capacity between 40%-100% based on demand. This flexibility cuts energy consumption by 18% compared to fixed-speed compressors, while its robust alloy steel components withstand continuous operation (up to 8,000 hours/year) without wear.

Unlike fully hermetic compressors (which require complete replacement if internal parts fail), the SLG series features a detachable cast iron housing. This design eliminates the need for costly unit replacements, reducing long-term maintenance expenses by 50% over the compressor’s 8+ year lifespan.

The compressor uses rubber-coated metal gaskets and precision-machined flange connections, achieving an annual leak rate of ≤0.3% (far below the industry average of 1.2% for open compressors). This not only reduces refrigerant waste but also complies with global environmental standards (e.g., EU F-Gas Regulation).

• Compressor Screws: Heat-treated alloy steel (HRC 58-62) resists wear from continuous rotation.

• Motor Windings: Class H insulation tolerates temperatures up to 155°C, preventing burnout in high-load conditions.

• Casing: Corrosion-resistant cast iron with a zinc-plated finish, suitable for harsh industrial or marine environments.

• Power Supply: 380-420V/50Hz/3ph (for 50Hz regions); 440-480V/60Hz/3ph (for 60Hz regions).

• Energy Regulation: 40%, 70%, 100% step regulation; optional stepless regulation (100%-40%).

• Protection Module: INT 69 RCY (includes overcurrent, overheating, and phase-loss protection).

• Max Discharge Temperature: 110°C (compatible with R404A/R507 refrigerants).

Our engineering team uses load-calculation software to match the correct SLG model to your system—considering factors like cooling capacity (kW), ambient temperature, and refrigerant type. This ensures optimal performance and avoids over-sizing (which wastes energy) or under-sizing (which causes compressor strain).

Certified technicians provide on-site guidance for wiring, piping, and refrigerant charging, adhering to safety standards (e.g., IEC 60335-2-34 for refrigeration equipment). We also offer 2-hour training sessions for your maintenance team to teach basic troubleshooting and routine checks.

• Warranty: 18 months on core components (motor, screws, seals); optional 2-year extension.

• Spare Parts: Global warehouse network (USA, Germany, China) ensures delivery within 3-5 business days for critical parts (e.g., gaskets, bearings).

A dedicated technical hotline (available in English, Spanish, and Mandarin) provides real-time solutions for issues like abnormal current, leaks, or temperature fluctuations. For urgent cases, we dispatch local service partners within 24 hours.

| Model | SLG | 100-35 | 120-40 | 140-50 | 190-65 | 210-70 | 230-80 | 290-100 | 320-110 | 350-120 | 370-130 | 420-145 | 470-160 | 520-180 | 570-195 | 640-210 |

| Displacement 50Hz | m3/h | 102 | 128 | 145 | 188 | 205 | 235 | 293 | 322 | 354 | 368 | 416 | 469 | 520 | 572 | 641 |

| Nominal Motor Power | Hp/kW | 40/30 | 40/30 | 50/37 | 70/52 | 70/52 | 80/60 | 100/75 | 115/83 | 120/89 | 130/98 | 145/108 | 160/120 | 180/135 | 195/146 | 210/157 |

| Weight | Kg | 245 | 245 | 255 | 405 | 410 | 420 | 535 | 540 | 545 | 665 | 675 | 710 | 1030 | 1050 | 1050 |

| Discharge line,internalΦ | mm | 45 | 45 | 45 | 57 | 57 | 57 | 57 | 57 | 57 | 76 | 76 | 76 | 76 | 76 | 76 |

| Suction line, internalΦ | mm | 57 | 57 | 57 | 76 | 76 | 76 | 89 | 89 | 89 | 89 | 89 | 89 | 108 | 108 | 108 |

| Energy regulation | 40%,70%,100%,Adujust or stageless 100…40% | |||||||||||||||

| Protection module | INT 69 RCY | |||||||||||||||

| Standard motor | 380V/3/50Hz-460/3/60Hz | |||||||||||||||

| Starting current | A | 134 | 134 | 139 | 193 | 193 | 298 | 338 | 354 | 366 | 453 | 453 | 543 | 595 | 678 | 767 |

| Maximum | A | 134 | 134 | 182 | 139 | 193 | 338 | 318 | 318 | 354 | 374 | 453 | 543 | 595 | 595 | 595 |

| working current | A | 56 | 60 | 78 | 104 | 109 | 126 | 158 | 175 | 187 | 206 | 228 | 253 | 284 | 308 | 331 |

Key/:

Qo:coolingcapacity/冷量( kW)

Pa :inputpower/输入电功率(kW)

Te :Evaporatingtemperature/蒸发温度(℃)

Tc:Condensingtemperature/冷凝温度(℃)

50Hzfrequency /频率

Liquid subcooling/液体过冷度 5K

Suction gas superheat/吸气过热度 10K

Require additionalcooling

| SLG | 120-40 | 140-50 | 160-60 | 190-65 | 210-70 | 230-80 | 250-90 | 290-100 | 350-120 | 420-150 | 520-180 | 640-220 |

| SLD | 120-30 | 140-40 | 160-50 | 190-50 | 210-60 | 230-70 | 250-75 | 290-80 | 350-100 | 420-125 | 520-160 | 640-200 |

| A | 338 | 390 | 480 | 425 | 540 | |||||||

| B | 232 | 290 | 290 | 360 | 340 | |||||||

| C | 96 | 120 | 115 | 145 | 170 | |||||||

| D | 276 | 309 | 327 | 326 | 417 | |||||||

| E | 965 | 1125 | 1243 | 1281 | 1509 | |||||||

| F | 255 | 285 | 316 | 352 | 377 | |||||||

| G | 545 | 590 | 646 | 717 | 757 | |||||||

| H | 410 | 475 | 450 | 495 | 535 | |||||||

| J | 325 | 371 | 378 | 427 | 465 | |||||||

| K | 134 | 165 | 150 | 158 | 181 | |||||||

| L | 766 | 850 | 995 | 1025 | 1167 | |||||||

| M | 208 | 216 | 247 | 286 | 296 | |||||||

| N | 267 | 290 | 290 | 340 | 350 | |||||||

| 供油管 Oil | 16 / 5/8" | 22 / 7/8" | ||||||||||

| 排气管 DLΦ | 45 / 1-5/8" | 57 / 2-1/8" | 67 / 2-5/8" | 76 / 3-1/8" | 89 / 3-5/8" | |||||||

| 吸气管 SLΦ | 57 / 2-1/8" | 76 / 2-5/8" | 89 / 3-1/8" | 89 / 3-5/8" | 108 / 4-1/8" | |||||||

content is empty!