close

Choose Your Site

Global

Social Media

| Horse Power: | |

|---|---|

| Power supply: | |

| Energy regulation: | |

| Availability: | |

| Quantity: | |

SLD

RFC

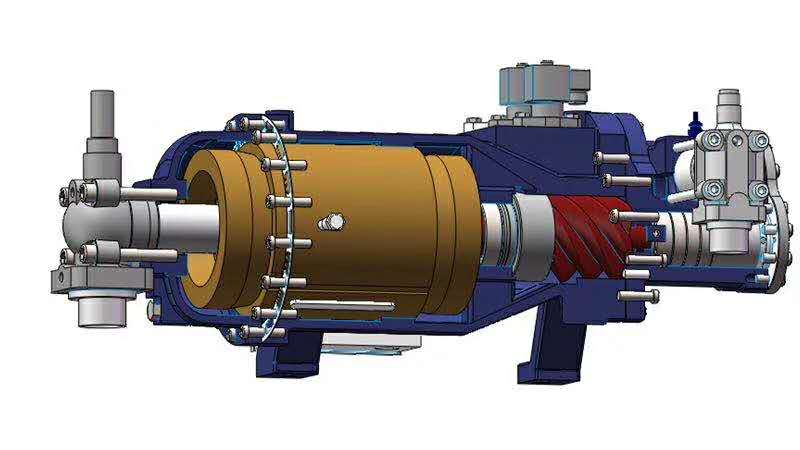

The Semi-Hermetic Screw Compressor LBP (SLD series) is optimized for low evaporating temperatures (-25°C to 10°C) and medium power (25-200 HP). It combines the maintainability of open compressors with the sealing reliability of hermetic units, making it ideal for temperature-sensitive applications where efficiency and cost control are critical.

Grocery store walk-in freezers and food processing cold rooms require stable -18°C to -25°C temperatures. The SLD series’ step/stepless energy regulation adapts to fluctuating loads (e.g., after restocking with warm goods), reducing energy use by 15% vs. fixed-speed compressors. Its low-noise operation (<75dB) also avoids disturbing store staff and customers.

Refrigerated trucks face constant vibration and temperature swings (from -10°C to 35°C). The SLD series’ robust casing (reinforced with steel brackets) and shock-absorbing motor mounts prevent component damage, while its tight sealing ensures no refrigerant leaks—critical for keeping meat, dairy, or pharmaceuticals fresh during 8-12 hour deliveries.

For plastic extrusion or packaging lines, small chillers (5-20 tons) need compact, easy-to-maintain compressors. The SLD series’ removable housing allows on-site repairs (no need to disassemble the entire chiller), cutting downtime from 48 hours (for hermetic units) to 6 hours.

The SLD series features modified screw profiles and an oil cooling system (A1/A2 cooling modes) that prevent oil thickening at -25°C. This ensures smooth lubrication and consistent compression efficiency, even in ultra-low temperature conditions—unlike standard compressors, which lose 20% efficiency at sub-zero temperatures.

To address the biggest issue with open compressors (shaft seal leaks), the SLD series uses a dual-seal design: an inner mechanical seal (for refrigerant retention) and an outer dust seal (for debris protection). This achieves an annual leak rate of ≤0.5%, complying with strict environmental regulations (e.g., EPA 608 in the USA).

• Casing: High-strength cast iron (30% lighter than steel) with an epoxy coating, resistant to humidity and chemical fumes in industrial settings.

• Compressor Screws: Nickel-plated alloy steel, which resists wear from R404A/R507 refrigerants (common in low-temperature systems).

• Motor Bearings: Ceramic hybrid bearings (heat-resistant up to 180°C) for long-term reliability.

• Power Supply: 380-420V/50Hz/3ph; 440-480V/60Hz/3ph (compatible with global grids).

• Energy Regulation: 40%, 70%, 100% step regulation; stepless 100%-40% (optional).

• Protection Module: INT 69 RCY (overcurrent, overheating, phase-reverse protection).

• Refrigerant Compatibility: R404A/R507 (optimized for low-temperature use).

We use specialized software (e.g., Carrier Hourly Analysis Program) to calculate your exact cooling needs—considering factors like freezer volume, insulation thickness, and door opening frequency. This ensures you select the right SLD model, avoiding energy waste or performance gaps.

Our team provides 4-hour training sessions on:

• Proper wiring (to avoid phase-reverse damage).

• Refrigerant charging (to prevent liquid slugging).

• Compliance with ASHRAE 15 (safety standard for refrigeration systems).

We also supply detailed installation manuals with diagrams for local technicians.

• Standard Warranty: 18 months on all components; 24 months if you use our recommended refrigerants (R404A/R507).

• Maintenance Contracts: Optional annual plans include oil changes, leak testing, and seal inspections—extending compressor life by 3 years.

For critical applications (e.g., refrigerated trucks), we offer 24/7 emergency support. Local service partners can reach most locations within 48 hours, and we stock emergency parts (e.g., seals, fuses) in regional warehouses.

| Model | SLD | 100-25 | 120-30 | 140-40 | 190-50 | 210-60 | 230-70 | 290-80 | 320-90 | 350-100 | 370-110 | 420-120 | 470-140 | 520-160 | 570-175 | 640-190 |

| Displacement 50Hz | m3/h | 102 | 128 | 145 | 188 | 205 | 235 | 293 | 322 | 354 | 368 | 416 | 469 | 520 | 572 | 641 |

| Nominal Motor Power | Hp/kW | 30/22 | 30/22 | 40/30 | 60/45 | 60/45 | 70/53 | 80/60 | 90/68 | 100/75 | 110/83 | 120/89 | 140/105 | 160/120 | 175/131 | 200/143 |

| Weight | Kg | 245 | 245 | 255 | 405 | 410 | 420 | 535 | 540 | 545 | 665 | 675 | 710 | 1030 | 1050 | 1050 |

| Discharge line,internalΦ | 45 | 45 | 45 | 57 | 57 | 57 | 57 | 57 | 57 | 76 | 76 | 76 | 76 | 76 | 76 | |

| Suction line, internalΦ | mm | 57 | 57 | 57 | 76 | 76 | 76 | 89 | 89 | 89 | 89 | 89 | 89 | 108 | 108 | 108 |

| Energy regulation | 40%,70%,100%,Adujust or stageless 100…40% | |||||||||||||||

| Protection module | INT 69 RCY | |||||||||||||||

| Standard motor | 380V/3/50Hz-460/3/60Hz | |||||||||||||||

| Starting current | A | 131 | 131 | 134 | 182 | 182 | 193 | 298 | 318 | 338 | 416 | 416 | 453 | 543 | 595 | 678 |

| Maximum | A | 131 | 131 | 134 | 182 | 182 | 193 | 298 | 318 | 338 | 416 | 416 | 453 | 543 | 595 | 678 |

| working current | A | 42 | 46 | 63 | 90 | 95 | 112 | 126 | 144 | 157 | 175 | 187 | 221 | 251 | 275 | 301 |

Key/:

Qo:coolingcapacity/冷量( kW)

Pa :inputpower/输入电功率(kW)

Te :Evaporatingtemperature/蒸发温度(℃)

Tc:Condensingtemperature/冷凝温度(℃)

50Hzfrequency /频率

Liquid subcooling/液体过冷度 5K

Suction gas superheat/吸气过热度 10K

Require additionalcooling

| SLG | 120-40 | 140-50 | 160-60 | 190-65 | 210-70 | 230-80 | 250-90 | 290-100 | 350-120 | 420-150 | 520-180 | 640-220 |

| SLD | 120-30 | 140-40 | 160-50 | 190-50 | 210-60 | 230-70 | 250-75 | 290-80 | 350-100 | 420-125 | 520-160 | 640-200 |

| A | 338 | 390 | 480 | 425 | 540 | |||||||

| B | 232 | 290 | 290 | 360 | 340 | |||||||

| C | 96 | 120 | 115 | 145 | 170 | |||||||

| D | 276 | 309 | 327 | 326 | 417 | |||||||

| E | 965 | 1125 | 1243 | 1281 | 1509 | |||||||

| F | 255 | 285 | 316 | 352 | 377 | |||||||

| G | 545 | 590 | 646 | 717 | 757 | |||||||

| H | 410 | 475 | 450 | 495 | 535 | |||||||

| J | 325 | 371 | 378 | 427 | 465 | |||||||

| K | 134 | 165 | 150 | 158 | 181 | |||||||

| L | 766 | 850 | 995 | 1025 | 1167 | |||||||

| M | 208 | 216 | 247 | 286 | 296 | |||||||

| N | 267 | 290 | 290 | 340 | 350 | |||||||

| 供油管 Oil | 16 / 5/8" | 22 / 7/8" | ||||||||||

| 排气管 DLΦ | 45 / 1-5/8" | 57 / 2-1/8" | 67 / 2-5/8" | 76 / 3-1/8" | 89 / 3-5/8" | |||||||

| 吸气管 SLΦ | 57 / 2-1/8" | 76 / 2-5/8" | 89 / 3-1/8" | 89 / 3-5/8" | 108 / 4-1/8" | |||||||

content is empty!