close

Choose Your Site

Global

Social Media

| Power supply: | |

|---|---|

| Lubricant: | |

| Horse power: | |

| Availability: | |

| Quantity: | |

4SG/4SD

DMZL

As a flagship product of Zhejiang Daming Refrigeration—with over 30 years of expertise in semi-hermetic compressor manufacturing—the 4SG/4SD series is engineered to address cooling pain points across food storage, industrial production, and commercial comfort systems. Its multi-refrigerant compatibility (R22, R404A, R134A, R507A) and compact design make it a go-to solution for:

• Food Cold Storage Facilities: Maintains stable temperatures (-18℃ to 5℃) in 100-500 m³ cold rooms, supporting daily restocking of 5-10 tons of frozen meats, dairy, or fresh produce without temperature fluctuations that risk spoilage.

• Industrial Manufacturing Lines: Cools heat-generating equipment like hydraulic systems, plastic injection molds, and electronic control panels in factories, ensuring consistent production under 30-45℃ ambient conditions.

• Mid-Sized Commercial Spaces: Powers central air conditioning for 5,000-10,000 m² office buildings and shopping malls, balancing cooling efficiency with low operational noise (≤75 dBA) to enhance user comfort.

The compressor features a semi-hermetic integrated structure (motor and crankcase cast as one unit), eliminating refrigerant leakage risks (leak rate < 0.1 g/year). Key manufacturing processes ensure reliability:

• CNC processing centers for cylinder bore machining (tolerance ±0.005mm) to minimize internal friction and energy loss.

• Automated assembly lines and ultrasonic cleaning systems to remove debris from components, preventing valve or bearing damage.

• 24-hour runtime testing in advanced laboratories to validate performance under varying load conditions.

• Crankcase & Cylinder Block: High-strength cast iron (HT300) with anti-corrosion treatment, supporting continuous operation for 15,000+ hours without structural wear.

• Pistons & Piston Rings: Lightweight aluminum alloy pistons paired with chrome-plated rings (wear resistance ≥ 5,000 hours), reducing mechanical resistance and improving energy efficiency.

• Valve Components: Imported spring steel (SUP9) for suction and discharge valves, ensuring fast response times and low vibration during operation.

• Free cooling system design services, including load calculation and compressor matching for cold rooms, industrial lines, or commercial spaces.

• Multi-language operation manuals and installation videos to guide on-site teams during setup.

• Customized maintenance plans: Lubricating oil replacement every 4,000 hours, valve plate inspection every 10,000 hours, and 24/7 online troubleshooting for urgent issues.

• Global spare parts warehouses (Shanghai, Dubai, Houston) ensuring fast delivery of replacement components (3-7 days for most regions).

• OEM/ODM services for non-standard voltage (e.g., 220-240V/3/50) or frequency (60Hz) requirements to match regional power grids.

• 18-month standard warranty (36 months for core components like crankshafts and motors) to cover manufacturing defects.

• Logistics flexibility: MOQ 10 units, monthly production capacity 5,000 units, and shipment from Ningbo port with support for L/C or T/T payment terms.

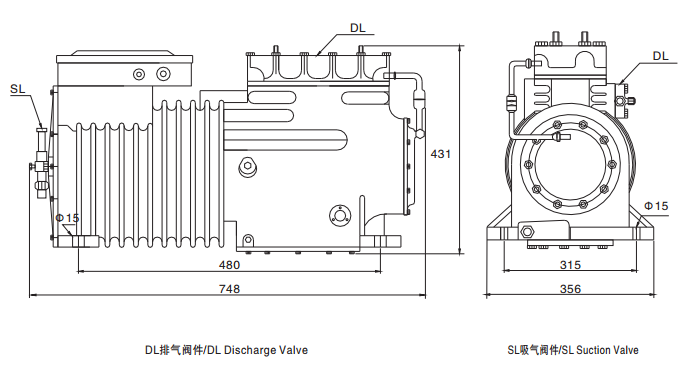

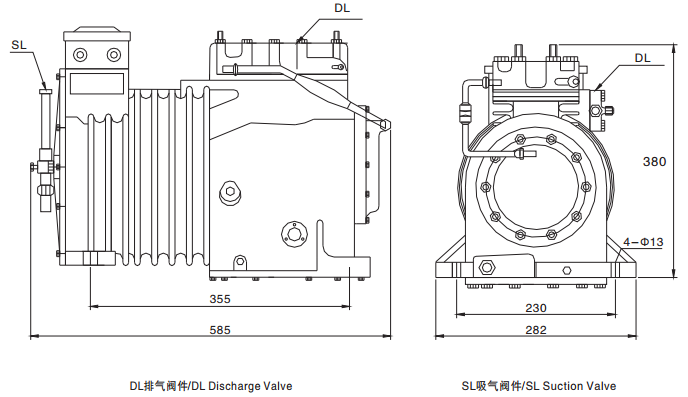

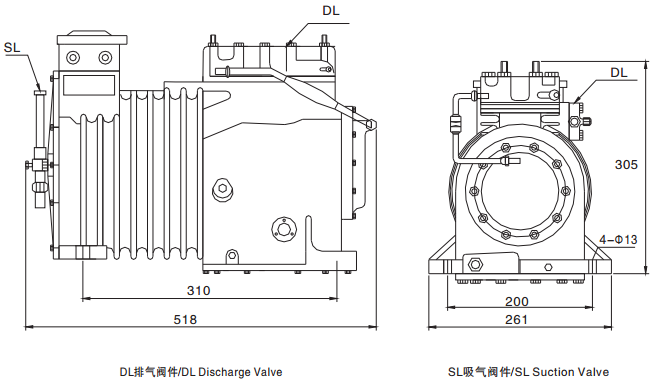

| C TYPE Model | Nominal Power HP/KW | Displacement m³/h@ 50Hz | Number of Cylinders×Diameter×Stoke | Exhaust & Suction Valve mm/IN | Oil Volume L | Power V/φ/Hz | Electrical Parameter | Crankcase Heater (220V)W | Oil Supply Method | Weight (with lubricant) Kg | ||

| DL Exhaust Valve | SL Suction Valve | Max Operating Current (A) | Starting/ Locked Current (A) | |||||||||

| 4S151D | 15/10.5 | 73.7 | 4×φ70×55 | Φ28 | Φ42 | 4 | 380-420YY/3/50 440-480YY/3/60 | 31 | 81/132 | 140 | Forced-lubrication | 183 |

| 4S251G | 25/18.5 | 73.7 | 4×φ70×55 | Φ28 | Φ54 | 4.5 | 380-420YY/3/50 440-480YY/3/60 | 45 | 116/193 | 140 | Forced-lubrication | 203 |

| 4S201D | 20/15 | 84.6 | 4×φ75×55 | Φ28 | Φ54 | 4.5 | 380-420YY/3/50 440-480YY/3/60 | 37 | 97/158 | 140 | Forced-lubrication | 192 |

| 4S301G | 30/22 | 84.6 | 4×φ75×55 | Φ28 | Φ54 | 4.5 | 380-420YY/3/50 440-480YY/3/60 | 53 | 135/220 | 140 | Forced-lubrication | 206 |

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | |||||||||||||||

| Evaporating Temperature ℃ | |||||||||||||||||

| 12.5 | 10 | 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | -50 | |||

| 4S151D | 30 | Qo | 52300 | 42700 | 34450 | 27350 | 21300 | 16400 | 12000 | 8310 | |||||||

| Pe | 12.73 | 11.93 | 11.01 | 9.98 | 8.82 | 8.25 | 7.13 | 5.98 | |||||||||

| 40 | Qo | 46850 | 38100 | 30500 | 24050 | 18500 | 13840 | 9800 | 6440 | ||||||||

| Pe | 14.91 | 13.81 | 12.56 | 11.19 | 9.76 | 8.67 | 7.3 | 5.9 | |||||||||

| 50 | Qo | 41700 | 33700 | 26800 | 20900 | 15800 | 11500 | 7920 | 4970 | ||||||||

| Pe | 17.11 | 15.67 | 14.13 | 12.47 | 10.85 | 9.21 | 7.53 | 5.79 | |||||||||

| 4S251G | 30 | Qo | 99300 | 91200 | 83600 | 76500 | 63700 | 52600 | 42950 | 34650 | 27500 | 21400 | 16260 | ||||

| Pe | 13.89 | 13.74 | 13.56 | 13.34 | 12.84 | 12.22 | 11.48 | 10.63 | 9.67 | 8.59 | 7.41 | ||||||

| 40 | Qo | 89700 | 82300 | 75400 | 68900 | 57300 | 47150 | 38350 | 30800 | 24250 | 18670 | 13940 | |||||

| Pe | 16.75 | 16.47 | 16.16 | 15.82 | 15.05 | 14.17 | 13.18 | 12.07 | 10.85 | 9.52 | 8.08 | ||||||

| 50 | Qo | 80500 | 73800 | 67600 | 61700 | 51100 | 41950 | 33950 | 27050 | 21100 | 16030 | ||||||

| Pe | 19.56 | 19.16 | 18.74 | 18.27 | 17.25 | 16.1 | 14.83 | 13.44 | 11.94 | 10.33 | |||||||

| 4S201D | 30 | Qo | 60000 | 48950 | 39500 | 31400 | 24500 | 18940 | 13920 | 9670 | |||||||

| Pe | 14.64 | 13.67 | 12.63 | 11.51 | 10.29 | 9.65 | 8.4 | 7.1 | |||||||||

| 40 | Qo | 53700 | 43700 | 35100 | 27750 | 21500 | 16080 | 11430 | 7530 | ||||||||

| Pe | 17.39 | 16.04 | 14.6 | 13.07 | 11.42 | 10.35 | 8.75 | 7.14 | |||||||||

| 50 | Qo | 47800 | 38750 | 30950 | 24200 | 18350 | 13390 | 9230 | 5790 | ||||||||

| Pe | 20.1 | 18.4 | 16.65 | 14.89 | 13.14 | 11.23 | 9.19 | 7.06 | |||||||||

| 4S301G | 30 | Qo | 114200 | 104800 | 96000 | 87800 | 73100 | 60400 | 49300 | 39800 | 31650 | 24700 | 18840 | ||||

| Pe | 16.42 | 16.23 | 16.01 | 15.74 | 15.11 | 14.33 | 13.44 | 12.45 | 11.36 | 10.21 | 9 | ||||||

| 40 | Qo | 103000 | 94500 | 86500 | 79100 | 65700 | 54000 | 44000 | 35350 | 27950 | 21650 | 16330 | |||||

| Pe | 19.78 | 19.46 | 19.09 | 18.68 | 17.74 | 16.67 | 15.49 | 14.2 | 12.83 | 11.4 | 9.92 | ||||||

| 50 | Qo | 92300 | 84600 | 77400 | 70700 | 58600 | 48100 | 39000 | 31200 | 24500 | 18810 | ||||||

| Pe | 23.4 | 22.9 | 22.3 | 21.7 | 20.4 | 19.04 | 17.57 | 16.05 | 11.49 | 12.91 | |||||||

| Based on 20℃ suction gas temperature,50Hz,without liquid subcooling. | |||||||||||||||||

| VARICOOL system,additional cooling,position of suction valve changed. | |||||||||||||||||

| Additional cooling or limited suction gas temperature. | |||||||||||||||||

| Additional cooling and CIC system. | |||||||||||||||||

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | ||||||||||||

| Evaporating Temperature ℃ | ||||||||||||||

| 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| 4S151D | 30 | Qo | 58500 | 48400 | 39700 | 32200 | 25750 | 20250 | 15560 | 11630 | 8350 | |||

| Pe | 15.78 | 14.84 | 13.79 | 12.63 | 11.40 | 10.10 | 8.77 | 7.43 | 6.10 | |||||

| 40 | Qo | 49850 | 41150 | 33600 | 27100 | 21500 | 16730 | 12660 | 9240 | 6380 | ||||

| Pe | 18.16 | 16.80 | 15.34 | 13.82 | 12.25 | 10.65 | 9.05 | 7.47 | 5.93 | |||||

| 50 | Qo | 33950 | 27600 | 22050 | 17330 | 13270 | 9820 | 6920 | ||||||

| Pe | 18.50 | 16.67 | 14.80 | 12.91 | 11.03 | 9.17 | 7.37 | |||||||

| 4S251G | 30 | Qo | 90700 | 83200 | 69700 | 57900 | 47750 | 38950 | 31350 | 24800 | 19210 | 14460 | 10460 | |

| Pe | 16.14 | 16.07 | 15.72 | 15.14 | 14.36 | 13.41 | 12.32 | 11.11 | 9.81 | 8.46 | 7.08 | |||

| 40 | Qo | 77400 | 71000 | 59500 | 49400 | 40650 | 33000 | 26450 | 20800 | 15930 | 11800 | 8320 | ||

| Pe | 19.56 | 19.22 | 18.37 | 17.32 | 16.11 | 14.76 | 13.31 | 11.78 | 10.20 | 8.60 | 7.00 | |||

| 50 | Qo | 64500 | 59100 | 49500 | 41000 | 33600 | 27200 | 21600 | 16830 | 12740 | 9260 | 6340 | ||

| Pe | 22.78 | 22.18 | 20.84 | 19.33 | 17.71 | 15.98 | 14.18 | 12.34 | 10.49 | 8.65 | 6.86 | |||

| 4S201D | 30 | Qo | 67100 | 55500 | 45400 | 36750 | 29350 | 23000 | 17600 | 13060 | 9260 | |||

| Pe | 18.22 | 17.12 | 15.89 | 14.55 | 13.12 | 11.62 | 10.08 | 8.53 | 6.97 | |||||

| 40 | Qo | 57200 | 47300 | 38700 | 31200 | 24800 | 19250 | 14540 | 10540 | 7160 | ||||

| Pe | 20.94 | 19.36 | 17.68 | 15.93 | 14.13 | 12.30 | 10.47 | 8.65 | 6.89 | |||||

| 50 | Qo | 38750 | 31650 | 25450 | 20100 | 15480 | 11510 | 8120 | ||||||

| Pe | 21.25 | 19.15 | 17.02 | 14.87 | 12.73 | 10.63 | 8.60 | |||||||

| 4S301G | 30 | Qo | 103800 | 95300 | 79900 | 66500 | 54900 | 44900 | 36250 | 28800 | 22450 | 17040 | 12480 | |

| Pe | 19.21 | 19.07 | 18.57 | 17.81 | 16.84 | 15.70 | 14.41 | 13.02 | 11.57 | 10.09 | 8.61 | |||

| 40 | Qo | 89100 | 81800 | 68600 | 57000 | 47000 | 38250 | 30700 | 24200 | 18610 | 13860 | 9850 | ||

| Pe | 23.37 | 22.88 | 21.73 | 20.38 | 18.88 | 17.26 | 15.56 | 13.81 | 12.06 | 10.33 | 8.68 | |||

| 50 | Qo | 74300 | 68200 | 57100 | 47400 | 38900 | 31500 | 25100 | 19580 | 14840 | 10810 | 7410 | ||

| Pe | 27.01 | 26.20 | 24.46 | 22.58 | 20.60 | 18.56 | 16.50 | 14.45 | 12.45 | 10.54 | 8.76 | |||

| Based on 20℃ suction gas temperature,50Hz,without liquid subcooling. | ||||||||||||||

| Additional cooling or limited suction gas temperature. | ||||||||||||||

| Additional cooling and CIC system. | ||||||||||||||

| Model | Condensing Temperature℃ | Cooling Capacity Qo(W) Power Consumption Pe(kW) | |||||||||||

| Evaporating Temperature ℃ | |||||||||||||

| 12.5 | 10 | 7.5 | 5 | 0 | -5 | -10 | -15 | -20 | -25 | -30 | |||

| 4S151D | 30 | Qo | 69100 | 62800 | 57000 | 51600 | 49150 | 33700 | 26700 | 20850 | 15920 | 11840 | 8500 |

| Pe | 10.40 | 10.07 | 9.74 | 9.41 | 8.74 | 8.07 | 7.38 | 6.67 | 5.95 | 5.20 | 4.42 | ||

| 40 | Qo | 61300 | 55700 | 50400 | 45600 | 37000 | 29600 | 23350 | 18100 | 13700 | 10060 | 7080 | |

| Pe | 12.46 | 11.93 | 11.43 | 10.93 | 9.97 | 9.04 | 8.13 | 7.23 | 6.32 | 5.39 | 4.44 | ||

| 50 | Qo | 54100 | 49050 | 44400 | 40100 | 32400 | 25800 | 20250 | 15570 | 11660 | 8430 | 5800 | |

| Pe | 14.24 | 13.54 | 12.87 | 12.22 | 10.99 | 9.81 | 8.69 | 7.59 | 6.51 | 5.43 | 4.34 | ||

| 4S251G | 50 | Qo | 54100 | 49050 | 44400 | 40100 | 32400 | 25800 | 20250 | 15570 | 11660 | ||

| Pe | 13.77 | 13.13 | 12.52 | 11.92 | 10.78 | 9.68 | 8.62 | 7.58 | 6.55 | ||||

| 60 | Qo | 47100 | 42700 | 38600 | 34800 | 28000 | 22200 | 17320 | 13190 | 9760 | |||

| Pe | 15.04 | 14.27 | 13.53 | 12.81 | 11.44 | 10.13 | 8.89 | 7.69 | 6.53 | ||||

| 70 | Qo | 40250 | 36450 | 32900 | 29600 | 23750 | 18740 | 14500 | 10940 | 7980 | |||

| Pe | 16.09 | 15.21 | 14.36 | 13.53 | 11.96 | 10.48 | 9.07 | 7.74 | 6.45 | ||||

| 4S201D | 30 | Qo | 78500 | 71400 | 64800 | 58600 | 47700 | 38350 | 30450 | 23800 | 18190 | 13560 | 9770 |

| Pe | 12.45 | 12.15 | 11.83 | 11.50 | 10.78 | 10.00 | 9.16 | 8.26 | 7.31 | 6.32 | 5.28 | ||

| 40 | Qo | 69700 | 63300 | 57400 | 51900 | 42100 | 33750 | 26650 | 20700 | 15700 | 11570 | 8190 | |

| Pe | 14.65 | 14.14 | 13.62 | 13.09 | 12.03 | 10.95 | 9.85 | 8.73 | 7.59 | 6.44 | 5.28 | ||

| 50 | Qo | 61500 | 55800 | 50500 | 45650 | 36950 | 29500 | 23200 | 17870 | 13430 | 9760 | 6770 | |

| Pe | 16.67 | 15.93 | 15.20 | 14.48 | 13.06 | 11.67 | 10.31 | 8.97 | 7.66 | 6.37 | 5.10 | ||

| 4S301G | 50 | Qo | 61500 | 55800 | 50500 | 45650 | 36950 | 29500 | 23200 | 17870 | 13430 | ||

| Pe | 16.09 | 15.42 | 14.76 | 14.10 | 12.79 | 11.50 | 10.22 | 8.94 | 7.67 | ||||

| 60 | Qo | 53700 | 48650 | 44000 | 39700 | 32000 | 25450 | 19890 | 15210 | 11300 | |||

| Pe | 17.65 | 16.80 | 15.96 | 15.14 | 13.54 | 11.99 | 10.49 | 9.03 | 7.60 | ||||

| 70 | Qo | 45900 | 41600 | 37600 | 33850 | 27200 | 21550 | 16720 | 12680 | 9320 | |||

| Pe | 19.22 | 18.16 | 17.14 | 16.15 | 14.25 | 12.46 | 10.75 | 9.12 | 7.55 | ||||

| Suction gas temperature 20℃,50Hz,without liquid subcooling. | |||||||||||||

| Additional cooling or limited suction gas temperature. | |||||||||||||

What are the structural design features of the compressor, and what problems can they solve?

It adopts a semi-hermetic integrated structure (the motor and crankcase are cast as one), which can significantly reduce the risk of refrigerant leakage, with a leakage rate of <0.1g/year. Meanwhile, the cylinder bore is processed by a CNC machining center (with a tolerance of ±0.005mm), reducing internal friction and energy consumption, and improving operating efficiency.

What materials are used for key components, and what durability advantages do they have?

Crankcase and cylinder block: High-strength HT300 cast iron (treated with anti-corrosion), supporting continuous operation for more than 15,000 hours without structural wear.

Piston and piston ring: Lightweight aluminum alloy piston + chromed piston ring, with a wear-resistant duration of ≥5,000 hours, reducing mechanical resistance and improving energy efficiency.

Valve assembly: Imported SUP9 spring steel (suction and discharge valves), featuring fast response speed and low vibration during operation.

What processes are used in the production process to ensure reliability?

These include an automated assembly line, ultrasonic cleaning of parts (to avoid damage to valves/bearings), and a 24-hour laboratory load test before delivery, ensuring stable performance under different working conditions.